Challenges of Operating Sawmills in Limited Spaces

Timber mills that don't have a lot of space face some tough problems. They need to set up their equipment in a special way to keep things running smoothly without making the quality of their output worse. One big headache is figuring out the best place to put all the machinery. It's like a big jigsaw puzzle, trying to fit everything in just right. Then there's the issue of managing how the materials move around. In a small space, it's easy for things to get clogged up. And let's not forget about following safety rules, which can be extra tricky when there's not much room to work with. Operators in these mills really have to think hard. They need to plan smartly and choose the right equipment so that they can still produce a good amount of timber, even though they're working in a tight space.

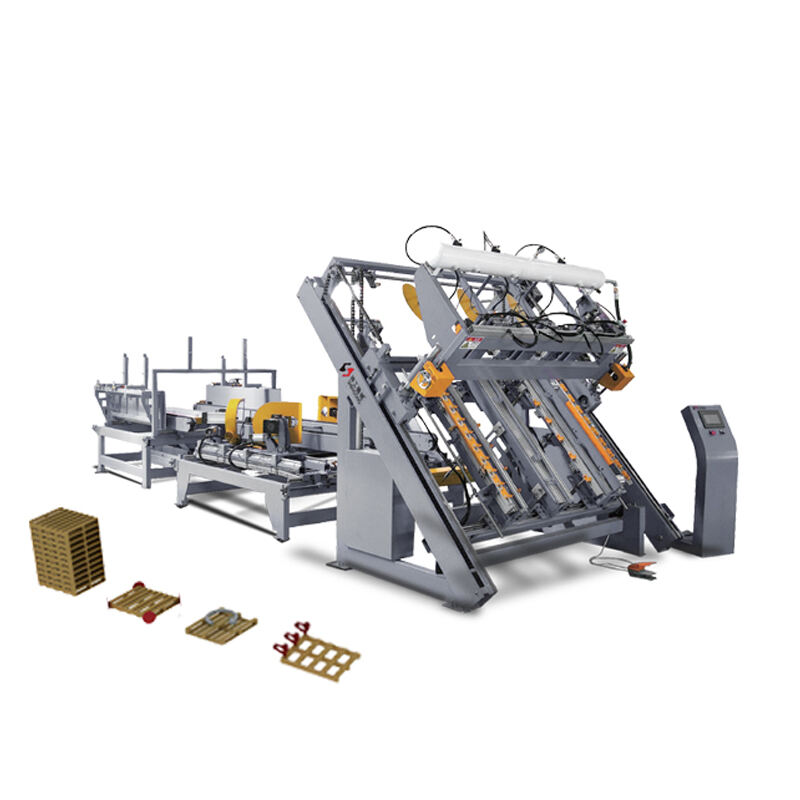

Essential Features of Compact Sawmill Lines

Now that we know about the challenges of running a sawmill in a limited space, let's talk about what kind of features a compact sawmill line should have. Modern compact sawmill solutions are really clever. They have the ability to stack things vertically. This means they don't take up as much horizontal space, which is precious in a small mill. The processing units are also multi - functional, which is a huge plus. Another important thing is that the key parts of the equipment should have adjustable positioning systems. This way, you can change how the equipment is set up depending on the size of the logs you're working with and what stage of processing you're at. And it's not just about the physical layout. Advanced dust collection systems are integrated, which is great for keeping the air clean in a small space. Centralized control systems are also a must. They make it easier to manage everything and still let the operators reach all the important parts.

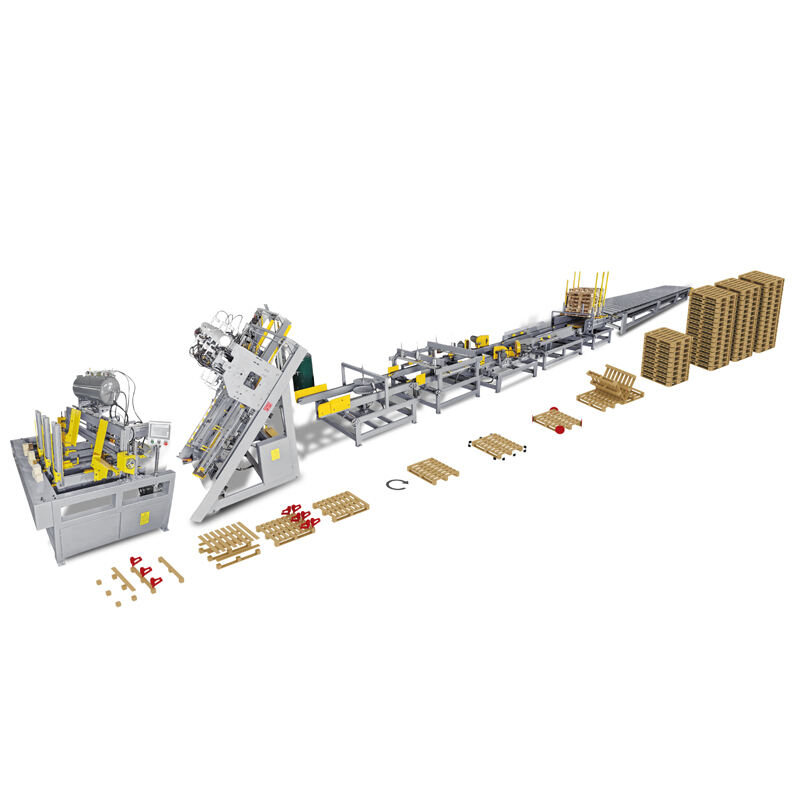

Optimizing Layout for Efficient Material Flow

Since we've covered the features of a compact sawmill line, let's focus on how to set up the layout to make the material flow smoothly. One really good way to do this is to use a U - shaped production line configuration. In a small space, this can be a game - changer. It cuts down on the amount of unnecessary moving around of materials. With this layout, the logs come in at one end, and as they go through the processing steps, they move in a nice, natural order until they become the finished product and are stored at the other end. Another smart idea is to put sorting conveyors above the processing equipment. This makes use of the vertical space, which is a great way to save room on the floor. And having retractable maintenance platforms is also useful. When you don't need to do maintenance, the platforms can be out of the way, so you have more floor area for the main operations.

Modular Equipment Advantages for Scalable Operations

Now, let's think about the future. If a timber mill in a small space wants to grow, modular equipment can be a big help. Modular sawmill systems are really flexible. If you think your mill might expand later, these pre - engineered units are perfect. You can start with what you need right now and still keep up your current production levels. As your business grows and you have more space or new processing needs, you can add on extra debarking stations or precision cutting modules. It's like building with Lego blocks. The modular approach makes it easy to adapt your mill over time, so you're always ready for whatever changes come your way.

Safety and Maintenance Considerations

Of course, in any timber mill, but especially in a small - space one, safety and maintenance are really important. In a condensed mill layout, you need to have really good safety protocols. This means having emergency stop systems that are easy to reach from all over the place. And you also need to plan the pathways for the workers carefully so they can move around safely. When it comes to equipment, choose ones that are easy to maintain. Front - loading service panels are great because they make it simple to get to the parts that need fixing. And if the mill has an overhead crane, make sure the equipment is compatible with it. Also, it's a good idea to regularly look at how the workflow is going. This way, you can spot any potential problems in the tightly - configured environment before they start to slow down production.