Understanding Core Requirements for New Pallet Manufacturers

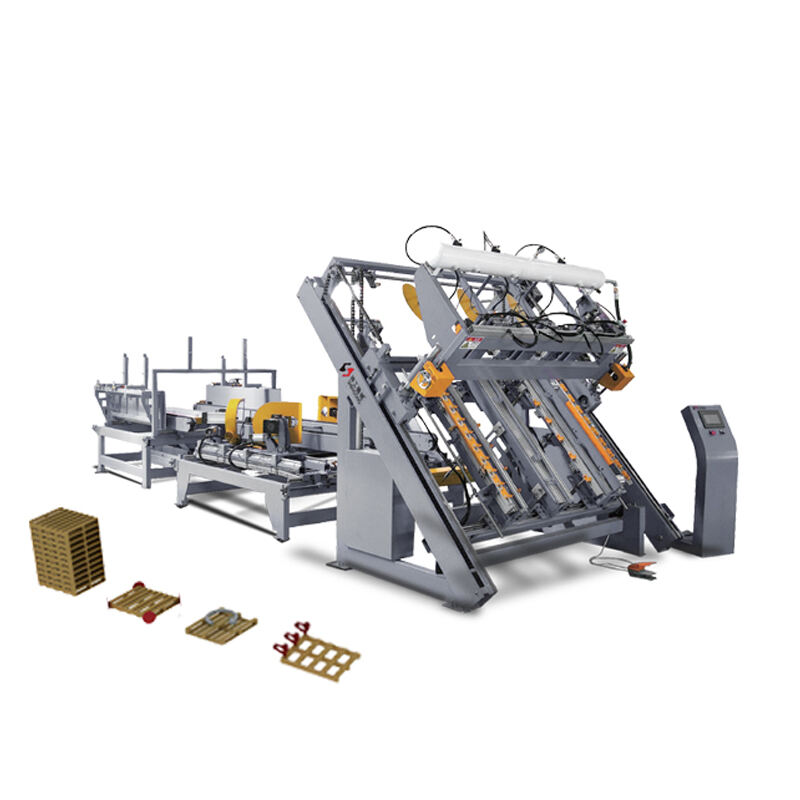

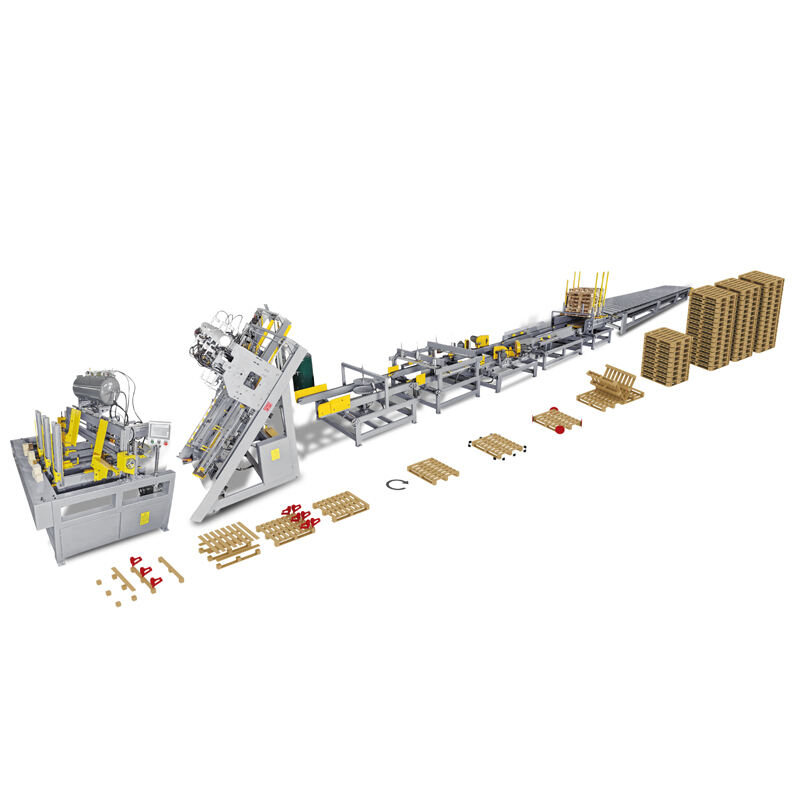

When you're just starting out in the pallet production business, it's super important to find the right equipment. You need a pallet nailing machine that works well but is also easy to use. In today's world, these machines should meet three main needs. First, they should be easy for operators to learn how to use. New people in the team shouldn't struggle too much to get the hang of it. Second, they should need as little maintenance as possible. You don't want to be constantly fixing the machine. And third, they should be able to work with different kinds of wood. How efficient your production is depends a lot on how easy the machine is to operate. Features like automated nail feeding systems, which put nails in place without much effort, and error detection mechanisms, which can tell if something's wrong, are really useful, especially for teams that don't have a lot of technical know - how.

Key Features to Prioritize in a Pallet Nailing Machine

Just because you want a machine that's easy to use doesn't mean it should be bad at its job. When you're looking for a pallet nailing machine, look for models that can adjust the pressure by themselves. This is really important because different types of wood have different densities. The machine needs to be able to handle that. Pneumatic systems are great too. They can provide a consistent force to drive the nails in, so all the nails go in the same way in every batch of pallets you make. Some advanced machines now have touch - screen interfaces that can be set to different languages. This is really helpful for new workers. They can learn how to use the machine much faster, and at the same time, you can still keep up the production standards.

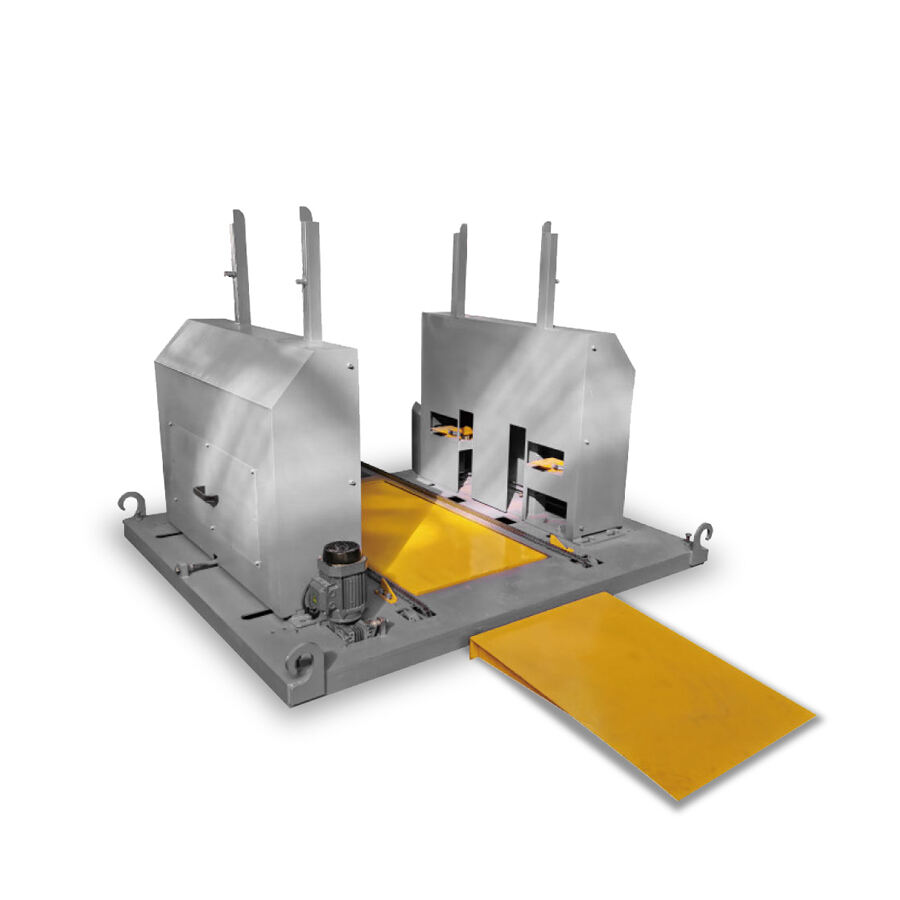

Optimizing Production Workflow Through Equipment Selection

Now that we know about the important features of a pallet nailing machine, let's talk about how the right choice of machinery can affect your whole production process. It's not just about how well one machine works. You should think about equipment with modular designs. This means that as your business grows, you can add more parts or upgrade the machine. Space is also a consideration. Look for models that are space - efficient and can stack vertically. This way, you can make the most of the space in your workshop. And if the machine can quickly change components to use different sizes of nails, it gives you more flexibility in your production schedule. Also, don't forget to think about how much energy the machine uses and how noisy it is. These things can affect your long - term operational costs.

Cost Considerations for Startup Operations

When you're starting a new business, you have to be careful about how you spend your money. You need to balance how much you spend on the machine at first with how much profit you expect to make later. Semi - automated models are often a good choice to start with. They can make your production 60 - 80% more efficient compared to doing it all by hand, and you don't need to know a lot about programming to use them. When you're looking at machines, check if they have durable cast - iron frames and if the replacement parts are easy to find and standard. This will help to reduce the time when the machine is broken and not working. Some manufacturers even have lease - to - own programs for new businesses. This can be really helpful because it lets you keep your money for other important things while you're growing your business.

Safety and Compliance in Pallet Machinery Operations

Of course, safety is a top priority in any business, especially when using machinery. When you're choosing a pallet nailing machine, make sure it has international safety certifications like CE or ISO. It should also have built - in protection features. For example, it should be able to shut down automatically if there's a jam. Magnetic nail feeders are good because they can stop nails from accidentally shooting out. And there should be emergency stop systems that can be reached from different places where the operators are working. Choosing the right machine in terms of safety not only keeps your workers safe but also makes sure you follow the safety rules that are always changing in the industry.

Implementing Preventive Maintenance Strategies

To make your pallet nailing machine last a long time, you need to take good care of it. Look for machines that have self - diagnostic systems. These can tell the operators when the machine needs lubrication or if a part is starting to wear out. You should also have a plan to clean the machine regularly to get rid of nail residue. And if you store the machine in a place where there's a lot of moisture, you need to control that. Many modern machines even have software that can keep track of when it's time to do maintenance. It does this based on how much the machine has been used, not just on a fixed schedule.