Key Features Industrial Woodworkers Should Prioritize

For industrial woodworkers who run large-scale operations, finding the right band saw is like finding a reliable partner. Precision and durability are two things you simply can't compromise on. Whether you're working with hardwoods that are tough as nails, engineered materials with specific requirements, or churning out products in high volumes, your band saw needs to deliver consistent cutting accuracy every single time. That's why you should look for models with a sturdy frame. A robust frame helps keep the machine steady, minimizing vibrations even when it's running non-stop. Advanced blade guidance systems are another must-have. They make sure the blade stays on track, so you get straight cuts even when dealing with dense materials. And variable speed controls are incredibly useful. They allow you to adjust the saw's speed based on the density of the timber you're working with. Plus, energy-efficient motors not only help you save on electricity bills but also provide the sustained power needed for long cutting sessions without overheating or losing torque.

Assessing Performance for Diverse Project Requirements

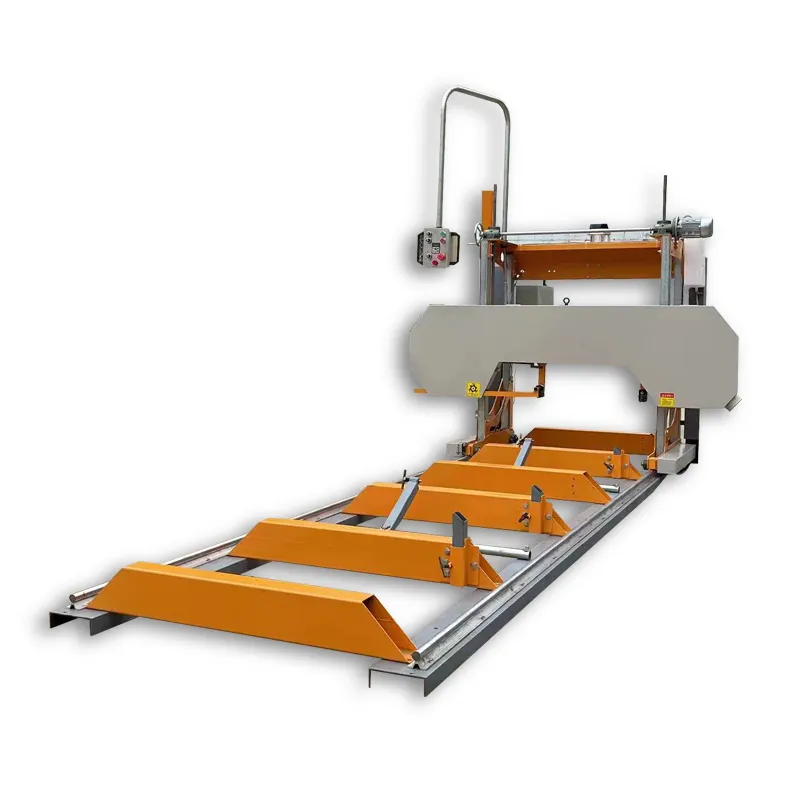

Today's manufacturing facilities often have to handle a wide variety of materials, and they need equipment that can keep up without sacrificing speed. A gantry band saw is a prime example of such versatile equipment. It offers enhanced stability, making it ideal for processing oversized timber that would be a challenge for other saws. When evaluating a band saw, you need to consider its cutting capacity in three dimensions: the maximum height, width, and throat depth of the workpiece it can handle. This ensures it matches the sizes of the materials you typically work with. Automated feed systems are also worth considering. They apply consistent pressure, which is crucial for getting uniform results, especially when you're dealing with knotty or irregular-grained wood that can be tricky to cut evenly. And don't forget about dust extraction compatibility. In a busy workshop with long shifts, having a saw that can work with a dust extraction system helps keep the air clean and healthy for everyone working there.

Maintenance Strategies for Prolonged Equipment Lifespan

In an industrial setting, every minute of downtime means lost money and productivity. To avoid this, it's essential to have a good maintenance strategy in place for your band saw. Predictive maintenance is a great approach. It involves monitoring things like blade tension and bearing wear patterns regularly. This way, you can spot potential problems before they turn into major breakdowns. Machines with accessible lubrication points and tool-free adjustment mechanisms are a godsend. They make it quick and easy to service the saw during breaks between shifts. Thermal overload protection is another important feature. It safeguards the motor during high-demand operations, preventing it from overheating and getting damaged. And by analyzing the recommended service intervals based on your production output volume, you can get a more accurate idea of the long-term costs of owning and operating the machine.

Safety Standards in High-Volume Production Environments

Safety should always be a top priority in any high-volume production environment, and when it comes to band saws, compliance with international machinery directives is non-negotiable. Not only does it protect the operators from harm, but it also keeps your business on the right side of the law. Look for saws that have emergency braking systems. These systems are designed to stop the blade within 10 seconds of activation, which can make all the difference in preventing serious injuries. Blade guards are another critical feature. They should provide complete coverage during both vertical and angled cuts, and interlock mechanisms should be in place to prevent the saw from operating if the safety zones are breached. Ergonomic design elements, like anti-fatigue platforms and vibration-dampened handles, are also important. They help reduce the physical strain on workers, especially those who are operating the saw for eight hours or more at a time.

Future-Proofing Your Woodworking Operations

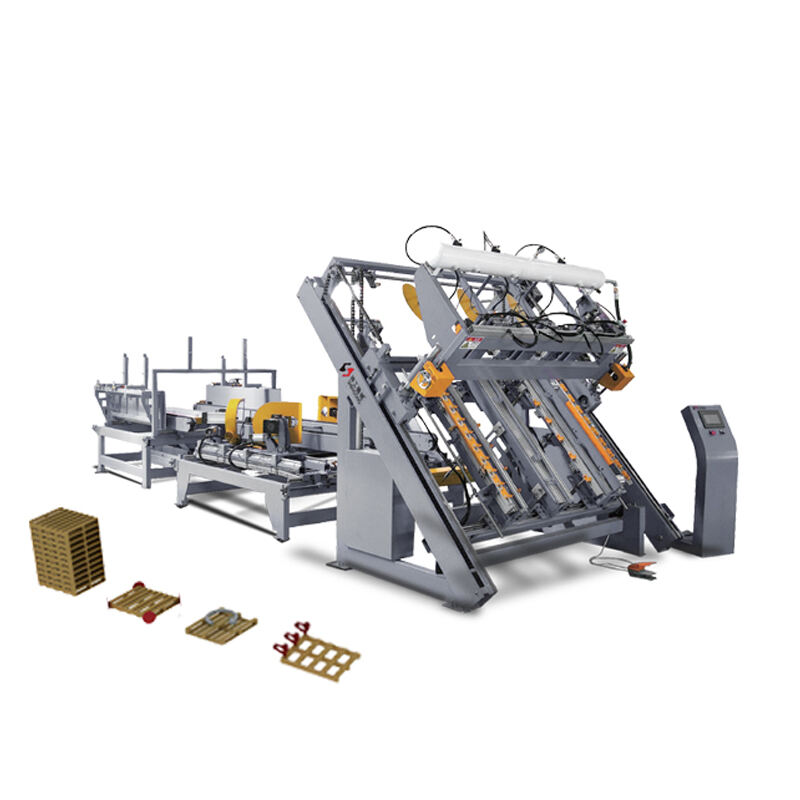

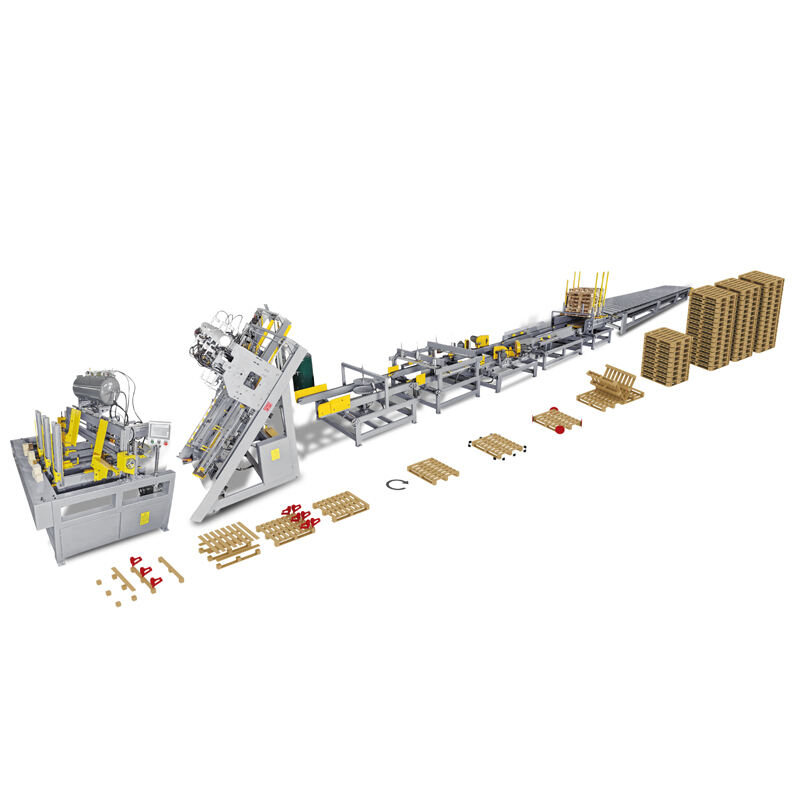

Investing in a band saw isn't just about meeting your current needs; it's also about preparing for the future of your woodworking business. Scalability is what sets an average piece of equipment apart from an exceptional investment. Band saws with modular designs are a great choice because they allow you to integrate additional features like laser alignment systems or automated sorting conveyors as your production requirements change over time. It's also a good idea to check if the machine is compatible with Industry 4.0 protocols. This enables data-driven performance tracking, giving you valuable insights into how the saw is operating and where improvements can be made. Some advanced models even come with predictive analytics capabilities. They can alert supervisors to potential maintenance needs before a failure occurs, helping you avoid unexpected downtime. And when considering a band saw, think about its resawing capacity and upgrade potential. These features ensure that you can adapt to new product lines without having to replace the entire machine, saving you time and money in the long run.