Understanding the Importance of Pallet Nailing Machines

Pallet quality matters a lot when it comes to keeping supply chains running smoothly. When companies use poor quality pallets, products get damaged during transport all the time. Some research shows that bad pallets cost businesses around $500 million each year in lost goods alone. These losses hit company wallets hard, but there's another problem too many people overlook. Damaged pallets cause serious headaches for logistics teams as well. They create delays at warehouses, mess up delivery schedules, and force workers to spend extra time inspecting shipments instead of moving them forward. For manufacturers who rely on just-in-time inventory systems, even small disruptions can ripple through their entire operation.

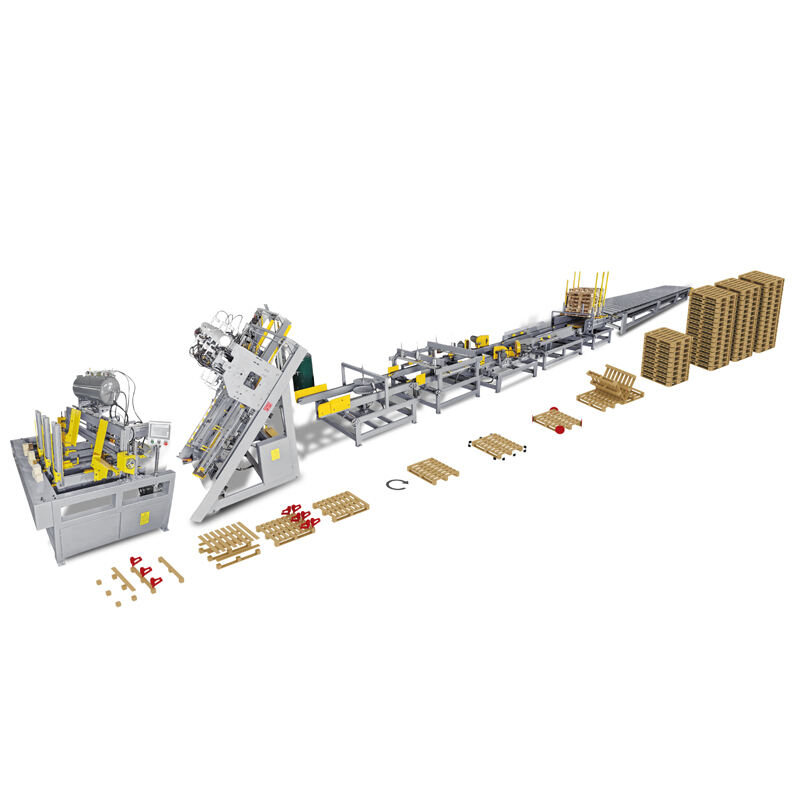

Pallet nailing machines really boost production efficiency, something manufacturers need when they're under pressure from rising demand. These automated systems handle the nailing work that would otherwise take hours of manual labor, cutting down both staffing expenses and assembly times across the board. Companies using this equipment find themselves better positioned to meet sudden spikes in orders without breaking a sweat, which keeps them ahead of competitors who still rely on traditional methods. The difference these machines make isn't just theoretical either – many warehouses report noticeable improvements in their supply chain performance after installation, helping entire sectors grow faster than before.

Types of Pallet Nailing Machines Available

Pallet nailing machines come in different varieties depending on what kind of work they need to do, each with its own advantages. Stringer models basically build pallets using wooden stringers, which works well for lighter stuff and keeps things simple both in terms of setup and daily operations. Block type machines are built differently though. They can take on much heavier loads because of how sturdy they are constructed, making them better suited for tough shipping requirements where pallet integrity matters most. For companies trying to get their pallet production sorted out without breaking the bank or wasting time, knowing when to choose one over the other makes all the difference in handling day to day logistics challenges across various industries.

Pallet nailing machines come in two main types when looking at how they work instead of just their physical build: automatic ones and those operated by hand. The automatic versions really shine in places needing lots of output quickly since they cut down on the need for workers to do all the nailing themselves. Factories running around the clock benefit from this speed boost while saving money on payroll expenses. Manual models have their place too though, especially for smaller shops or custom jobs where operators want control over every detail. A local workshop making specialty wooden crates might find these hand-operated machines give them that extra touch customers appreciate. So whether going full auto or keeping things hands-on depends largely on what kind of business model makes sense for each particular operation.

Top Factors to Consider When Choosing the Best Pallet Nailing Machines for Quality Pallets

Getting the right pallet nailing machine matters a lot when it comes to keeping production running smoothly and making good quality products. How fast things get done should be high on the list of things to check out before buying anything. Does the nailing machine actually handle what the business needs day to day? That's something worth figuring out early on. When machines match what operations need, there tend to be fewer holdups along the production line. Take Southern Packaging as an example they've had great results with their Viking Turbo 505 models because these machines just keep going at steady pace, so they never fall behind schedule no matter how busy things get around here.

How long something lasts matters a lot when talking about machines. Equipment made with strong materials tends to stick around for years without needing constant fixes. Companies that spend money upfront on good quality gear usually end up saving cash later because they don't have to stop operations so often for repairs. Take Southern Packaging for instance they switched to Viking Engineering products after seeing how much trouble their old stuff caused. Their switch to better built machines meant fewer breakdowns and smoother day to day running of their facility. Good manufacturing practices really pay off over time both in terms of wallet space and operational efficiency.

The ability to customize really makes all the difference when it comes to machine versatility. Equipment that handles different pallet dimensions and designs helps keep operations running smoothly day after day. When companies need to serve clients with varying requirements, they don't have to buy several machines just for small adjustments. Take Southern Packaging for instance they found that their flexible setup lets them produce quality pallets while staying ahead of competitors in the market. The Viking 505 model stands out here because it actually cuts down on time spent switching between setups, which means production can handle whatever comes next without missing a beat.

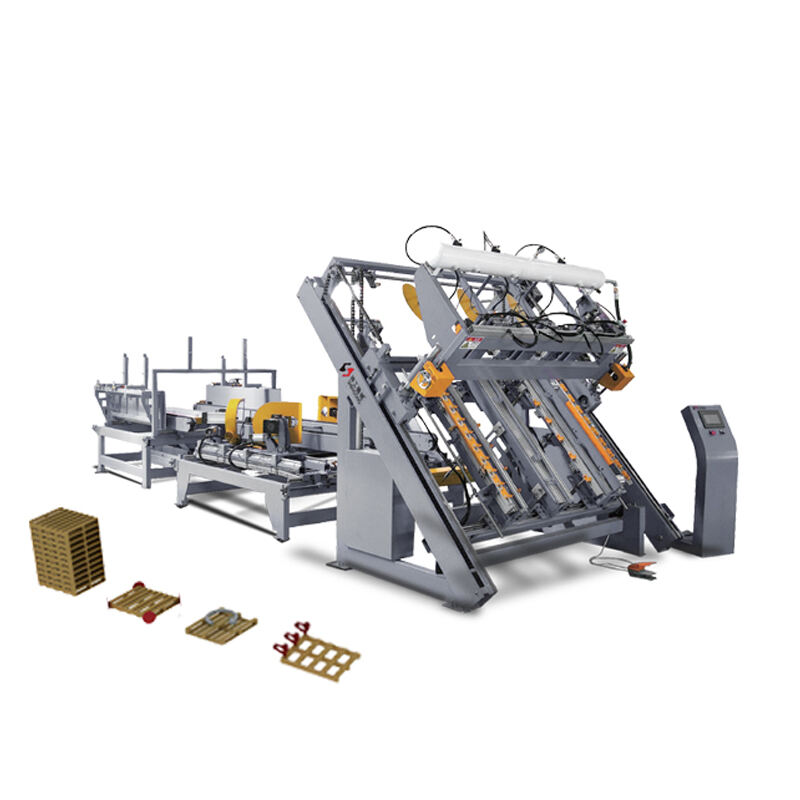

Product Review: Stringer Pallet Nailing Machine

For anyone looking to boost their pallet manufacturing output, the Stringer Pallet Nailing Machine delivers real results. This equipment puts together wooden pallets at impressive speeds while keeping nails in exactly the right spots. What makes it stand out? The whole system works so smoothly that each finished pallet comes out looking pretty much identical to the last one. That kind of consistency matters a lot when running a factory floor where downtime costs money. Most manufacturers will tell you reliable performance day after day is what keeps their operations running without constant headaches over defective products.

The machine boasts serious speed when it comes to nailing tasks, capable of driving nails at rates that would impress most production managers. It works well with softwoods like pine and fir as well as hardwoods such as oak and maple, so it fits into pretty much any woodworking shop setup. Safety isn't overlooked either there are built-in guards and emergency stop mechanisms that help keep operators safe during long shifts. For shops trying to get more done while keeping everyone on site protected, this equipment offers real value without forcing major changes to how things already work in the workshop environment.

This machine's blend of speed, precision, and reliability makes it a preferred option among manufacturers committed to producing high-quality pallets. Such attributes position it as a forerunner among pallet nailing machines, ensuring it meets the demands of modern production environments efficiently.

Comparative Analysis: Best Pallet Nailing Machines for Quality Pallets

Looking at top pallet nailing machines for making good quality pallets, Brand A and Brand B stand out in the market because they've got some really impressive tech built in. Both companies have developed automated nailing systems that actually work wonders for production lines. These systems cut down on assembly time significantly while keeping things safe for workers who operate them day after day. What's interesting is how these machines keep outputting consistently good results even when running non-stop through big orders. That kind of reliability matters a lot when factories need to meet tight deadlines without compromising on product standards.

People who buy these machines tend to talk about how long they last and how efficient they are, which explains why so many customers report being happy with their purchases. Most folks say picking equipment from established brands with good ratings makes all the difference for consistent performance over time. The bottom line is that spending money on reliable pallet nailing machines saves headaches later on when things break down or need constant fixing. Manufacturing shops that make this investment often see fewer interruptions in their workflow and save cash in the long run without compromising quality.

Investing in the Right Pallet Nailing Equipment

When companies think about getting into pallet nailing equipment, they really need to crunch some numbers first if they want their money to work hard for them. The whole point is looking at how much something costs when bought versus what it'll set them back month after month once it's running. Take those top shelf wood pallet nailers for example. Sure, they come with a bigger price tag right out of the box, but these machines tend to run smoother day in and day out. We've seen businesses save thousands down the road because these premium models break down less frequently and keep production lines moving without all those annoying stoppages. Most shop owners tell us the extra investment pays for itself within the first year or so through reduced repair bills alone.

Getting a handle on how much money we're actually making back from those pallet nailing machines matters a lot for any operation. Good quality equipment tends to speed things up quite a bit when it comes to putting together pallets, which means less waiting around and more cash flowing in. When production goes up, these machines pay for themselves pretty quickly and help keep the whole business running smoothly financially speaking. The newer models come packed with all sorts of fancy features too, so every penny spent on them ends up helping grow profits instead of just sitting there doing nothing.

Maintain and Troubleshoot Your Pallet Nailing Machines

Keeping pallet nailing machines well maintained isn't just good practice it's absolutely necessary if they're going to last through all those long shifts on the production floor. When operators take time to clean out debris from the nail feed area and swap out those worn drive belts before they snap, that goes a long way toward avoiding expensive downtime. Most shop managers know this from experience after watching some poor sap get stuck waiting for repairs during peak season. Regular checkups mean these machines keep running smoothly month after month, hitting those daily quotas without surprise stoppages that throw off the whole workflow.

Pallet nailing machines often face problems like missed shots from the nail gun or getting stuck altogether, both of which stop work until fixed. Being able to fix these issues fast means less time wasted and keeps operations moving forward. Operators who know their way around the machine's inner workings and electrical connections can usually sort out jams or bad firing without calling in outside technicians, which saves money and keeps projects on schedule. The pallet manufacturing business runs on tight margins, so every minute saved troubleshooting translates directly into better output numbers and healthier bottom lines for companies that stay ahead of equipment problems.

Frequently Asked Questions

What are the main benefits of using pallet nailing machines?

Pallet nailing machines enhance production efficiency by automating the nailing process, which reduces labor costs and assembly time. This helps businesses respond swiftly to market demands while maintaining competitive advantages.

How do I choose between a stringer and a block pallet nailing machine?

Stringer pallet nailing machines are ideal for lighter loads due to their simplicity, while block pallet nailing machines are better suited for heavier loads, providing essential durability and strength.

What factors should I consider when selecting a pallet nailing machine?

When selecting a pallet nailing machine, consider production rates, durability, and customization options to ensure that the machine meets your specific production demands and operational requirements.

How often should I perform maintenance on my pallet nailing machines?

Regular maintenance is crucial. It is advisable to perform routine checks and maintenance practices frequently to prevent breakdowns and ensure optimal performance and longevity of your pallet nailing machines.