Understanding Pallet Production and Its Challenges

Making wooden pallets happens through a manufacturing process that produces those flat platforms so important for moving goods around warehouses and distribution centers everywhere. To get started, manufacturers pick out good quality wood like Southern Yellow Pine or sometimes oak depending on what they need. Then comes the heavy equipment part where sawmills cut the boards to size and special pallet nailing machines put everything together quickly. Skilled workers still play a big role though, checking each pallet to make sure it can handle whatever gets stacked on top without falling apart. Most companies depend heavily on this whole setup just to keep up with how much stuff needs to be shipped these days across different sectors from food products to automotive parts.

Manual pallet making is running into some serious problems these days. Finding enough workers has gotten really tough, and when there aren't enough hands on deck, production slows down big time. The quality also tends to vary quite a bit from one batch to another. Some studies claim that businesses stuck with manual work actually miss out on around 20 percent efficiency gains compared to what they could achieve otherwise. That's not just numbers on paper either it translates directly into real money lost. When products come out looking different every time, customers get frustrated fast. We've all seen those boxes with crooked nails or uneven edges sitting on store shelves. Companies start seeing the light when they look at their bottom line though. More and more manufacturers are turning to automatic pallet nailing systems now. These machines handle repetitive tasks without getting tired or distracted, which means fewer mistakes overall and faster turnaround times for everyone involved.

The Advantages of a High-Quality Pallet Nailing Machine

Pallet nailing machines of good quality really speed things up in production shops. They automate where nails go and cut down on how long each cycle takes. Most modern models come equipped with smart controls that make switching between different jobs faster and keep running reliably even during long shifts. For companies needing to crank out hundreds or thousands of pallets daily, these machines are practically indispensable. The numbers back this up too industry insiders talk about productivity jumps around 70% when switching from hand nailing to automation. That kind of improvement makes all the difference when trying to meet tight deadlines while still keeping product standards high.

Keeping up consistent quality control matters a lot in pallet manufacturing, and automated nailing machines help keep things on track. These machines cut down on mistakes and defects so every pallet actually meets those tough industry requirements. When nails are off alignment or not properly secured, structural problems can pop up later on. That's why manufacturers rely on these precise machines to avoid such issues. The result? Pallets that look similar across the board and perform reliably whether they're shipping goods across town or halfway around the world.

High quality pallet nailing machines offer another big benefit that cuts down on labor expenses quite a bit. When companies automate the nailing process, they don't need as many workers doing manual assembly anymore. The money saved adds up fast when looking at things like wages, employee training programs, and health insurance costs. With skilled labor getting harder to find across manufacturing sectors right now, investing in automatic nailing equipment gives businesses an edge. Many shop owners report being able to keep production levels steady even during busy seasons without breaking the bank on overtime pay or hiring temps.

High-Quality Pallet Nailing Machine Benefits

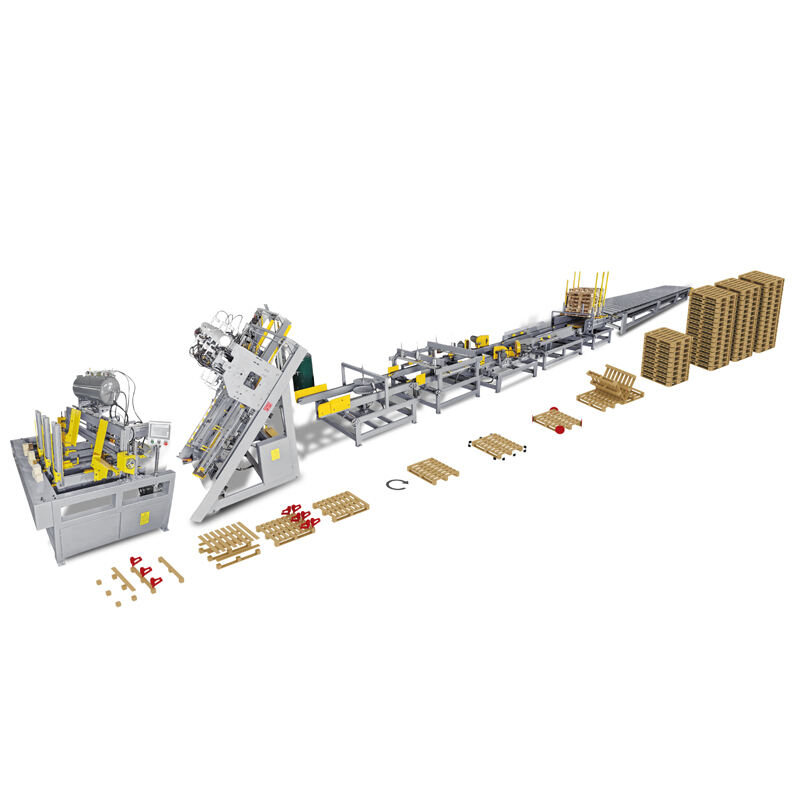

Better production capacity stands out as one major advantage when companies invest in quality pallet nailing equipment, resulting in much higher output levels. Take the Viking Turbo model for example many plant managers report seeing real improvements after switching to this machine. Some facilities have managed to crank out around 2000 pallets during a single work shift, according to what several manufacturers tell us. That kind of throughput makes a noticeable difference in profitability, especially when looking at long term operational costs versus initial investment expenses.

High quality machines make a big difference when it comes to cutting down on wasted materials during pallet production. These machines place nails exactly where they need to go and reduce mistakes, so almost nothing goes to waste in the process. Less waste means better for the environment obviously, but companies save money too since they don't have to buy as much raw material. Many businesses are finding that investing in good equipment pays off both ecologically and financially over time.

One major advantage comes from how well quality pallet nailing machines handle all sorts of pallets. Manufacturers can flip between different designs pretty easily without losing much time, which keeps their production running smoothly. These machines adjust quickly to whatever specs are needed for each job, so there's no need for big setup changes when orders come in with different requirements. This kind of flexibility really matters in today's manufacturing world where customers want everything done fast and customized.

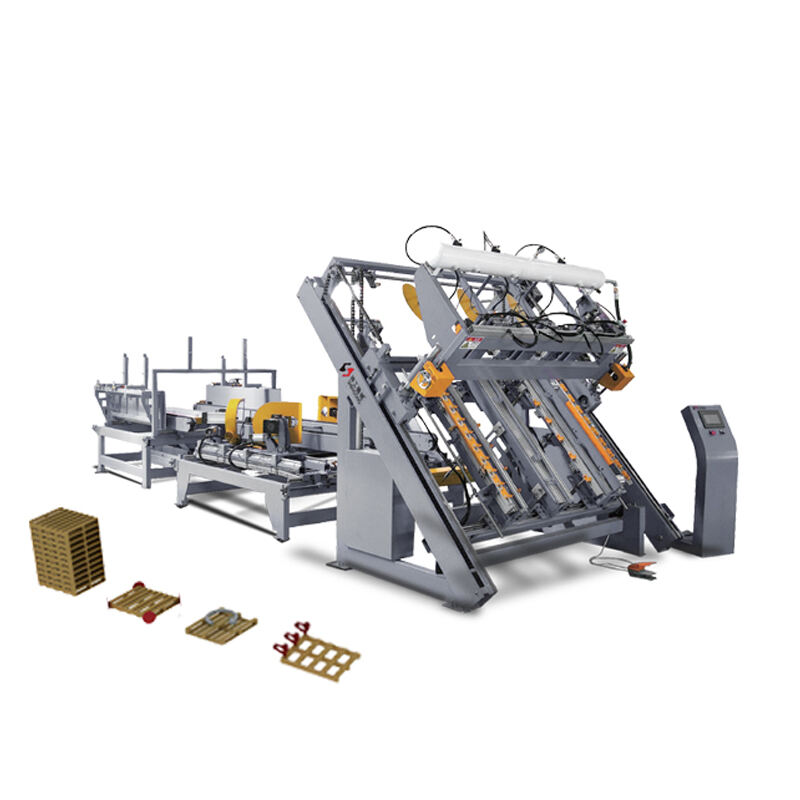

An Overview of the Stringer Pallet Nailing Machine

The Stringer Pallet Nailing Machine brings serious automation to the table, helping streamline production workflows across manufacturing facilities. It can handle pallet sizes anywhere from 800mm all the way up to 1300mm, and gets through around 4 to 7 pallets every single minute depending on setup. Power consumption varies quite a bit too, sitting somewhere between 20 KWh at minimum to as high as 330 KWh when running at full capacity. What really makes this machine stand out though is how consistently good quality comes out of it batch after batch. For anyone in the pallet business trying to boost output without sacrificing standards, this equipment becomes pretty much indispensable these days. Plus there's plenty of room for customization options built right in, so operators can tweak things according to what their particular line demands day to day.

Stringer pallet nailing machines bring real improvements in both efficiency and product stability. When the nailing gets automated, there's just less chance of mistakes happening during assembly. Every pallet coming off the line ends up meeting those tough quality requirements that warehouses demand. The result? Pallets that hold together better and won't fall apart mid-shipment. Plus, since workers don't have to handle as many tasks manually, production runs faster. Manufacturers can crank out more units while still keeping that same high standard of workmanship across all their output.

The stringer pallet nailing machine has proven itself useful in many different sectors throughout the manufacturing world. Companies big and small report better results when they incorporate this equipment into their workflow, mainly because it brings both speed and reliability to the table. Take logistics firms for example they've started using these machines to get their supply chains moving faster, which means products reach customers on time more often than not. Industry experts who've worked with the machines talk about how they completely changed things around on factory floors. Labor expenses dropped while production numbers went up, giving companies an edge over competitors who haven't made the switch yet.

Choosing the Right Pallet Nailing Machines

Getting the right pallet nailing machine makes all the difference when it comes to running a smooth operation and keeping those bottom line numbers looking good. First things first, think about how many pallets need to go out the door each day. If we're talking thousands per week, then investing in a full automation system would probably pay off faster than waiting for coffee to brew. But small shops often find themselves better off with something halfway there - maybe a semi-auto model that still gives workers enough control without slowing them down too much. What kind of pallets does the business actually make? Some machines work wonders on standard wooden crates while others specialize in specialty designs like block or stringer pallets. And let's not forget about money matters either. Take a close look at what these machines will cost over time, not just upfront price tags. Energy bills can add up fast if the equipment guzzles power, plus regular maintenance expenses should factor into any budget planning for the next few years at least.

Looking at various models available in the market requires focusing on important aspects such as how fast they work, how long they last, and what they cost. Take automatic pallet nailing machines as an example they tend to boost production rates significantly, often making them worth the extra money despite their initial expense. For anyone trying to sort out the options, organizing information into tables helps spot distinctions between models according to those main characteristics. Throw in some customer feedback and expert opinions too, since real world experiences can reveal things specs alone won't show.

Looking at costs against what we get back over time matters when figuring out if something is worth the money spent. A good pallet nailing machine isn't just another tool sitting around collecting dust. These machines actually boost how fast things get made on the factory floor while cutting down those frustrating stoppages during operations. The workforce doesn't need to spend as much time fixing problems either. As months go by, all these little gains start adding up. Production ramps up because everything runs smoother day after day. Products coming off the line look better too since there's less chance of mistakes happening. That means companies who invested wisely find themselves ahead of competitors in both price wars and customer satisfaction ratings across different markets they operate in.

The Future of Automated Pallet Production

Pallet nailing tech has changed a lot lately, mostly because manufacturers keep pushing automation and efficiency boundaries. Take automatic pallet nailing machines for instance they're completely changing the game when it comes to building pallets. The whole operation goes way quicker now, and there's less room for mistakes compared to old methods. Most companies prefer these automated systems since they cut down on hands-on work so much. Workers don't have to strain themselves as much anymore, plus the finished products tend to be more consistent across batches. Some factories report cutting production time in half after switching to this newer equipment.

Automation is changing how things work in the pallet manufacturing business. When companies bring automation into their operations, they usually see lower labor expenses while getting products out faster. Take pallet nailer machines with built-in smart tech for instance these days. These machines are making production lines run smoother than ever before. Manufacturers can now handle bigger orders without needing as many workers on hand. Some plants report cutting down on waste materials too, which makes sense when everything runs so efficiently from start to finish.

Things are changing fast in the world of pallet manufacturing right now. We're seeing manufacturers invest heavily in fully automated production lines while bringing smart tech into their operations. The big picture? Systems that don't just run themselves but also keep track of inventory levels and actually predict when parts might fail before they do. Many businesses have already started making this switch, and it's clear why. Pallet production becomes way more efficient with these upgrades, cutting down waste and downtime. For companies looking to stay ahead of the competition, getting onboard with automation isn't just an option anymore it's becoming something of a necessity if they want to keep up with customer demands and industry standards.

FAQs

What are the main challenges in manual pallet production?

Manual pallet production faces challenges such as labor shortages, inconsistent quality, and reduced production rates, which lead to inefficiencies and increased costs.

What advantages do automated pallet nailing machines offer?

Automated pallet nailing machines offer increased production speed, consistent quality, reduced labor costs, and the ability to produce large volumes efficiently.

How do I choose the right pallet nailing machine for my business?

Choose based on your production volume needs, the type of pallets you plan to produce, and the cost vs. long-term benefits including energy consumption and maintenance costs.

What is the future of pallet production technology?

The future is moving towards fully automated production lines with smart technologies allowing operations to be more efficient, predictive maintenance, and improved competitiveness.