Understanding the Multi Rip Saw Machine

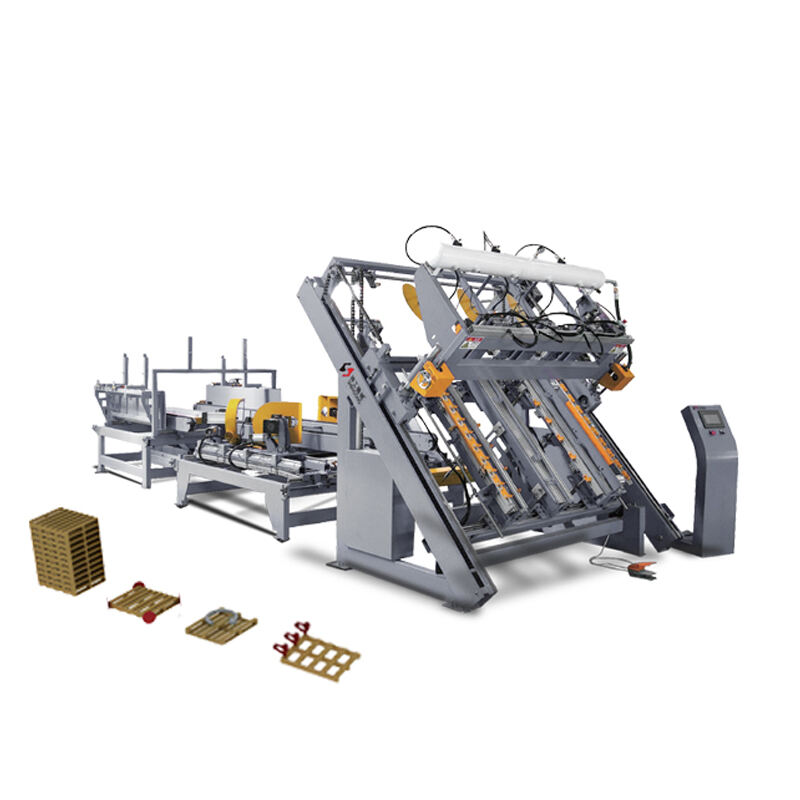

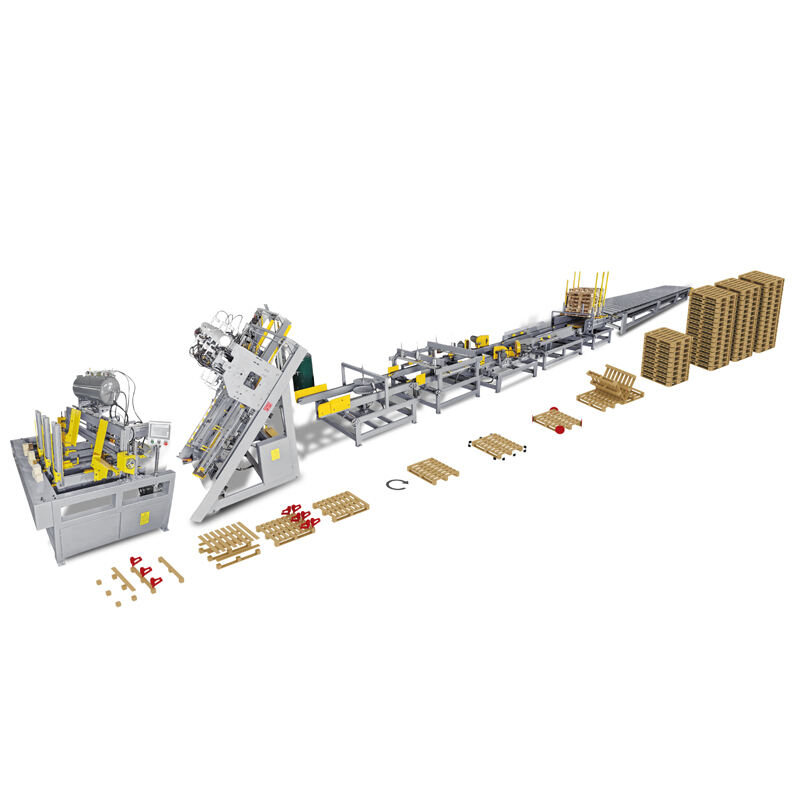

The multi rip saw machine stands out as one of those essential tools in any serious woodworking shop. Basically what it does is take those big chunks of timber and slice them down into neat, uniform sizes. Think of it as the workhorse when turning square logs into all sorts of useful wood products like bars and slats. What makes this machine special? Well, it packs several saw blades together so they can make multiple cuts at once something no regular single blade saw could ever match. For shops dealing with lots of lumber, this setup really pays off. The machine just keeps going through stacks of wood while maintaining pretty good accuracy too. Time saved equals money made after all.

Multi rip saw machines offer some real advantages for woodworking operations. These beasts boost productivity across the board since they can tackle different kinds of lumber without missing a beat, all while producing those clean, uniform cuts that most shops crave. The fact that everything comes out so consistently means there's way less need for extra sanding or touch ups down the line, which saves both time and money on material costs. And let's not forget about waste reduction either. When a shop runs through its stock faster with minimal scraps piling up, that translates directly into bottom line improvements. For furniture makers and cabinetry businesses especially, getting more done with fewer resources makes all the difference when competing in today's tight market conditions.

Key Specifications for Choosing a Multi Rip Saw

Choosing the right multi rip saw starts with looking at timber sizes and dimensions first. A saw needs to handle whatever log sizes come through the mill on a regular basis. Take note of those max numbers for thickness, width, and length of wood that gets processed most often. For thicker timber pieces, bigger blades become essential, and this actually changes how far apart the feed and discharge pressure wheels need to be positioned. Getting clear about what kind of widths, thicknesses, and minimum lengths we're dealing with makes all the difference when picking out the proper equipment for the job.

The kind of wood being cut makes a big difference when choosing specs for a multi rip saw. Hardwoods are much denser than softwoods, so they need machines with more power and special blades that can stand up to their tough nature. When working with hardwoods, operators often find themselves needing heavier duty equipment just to get through the material without damaging it. On the flip side, softwoods generally work fine with standard setups since they don't require as much force during cutting operations. Getting this right matters because it keeps the saw running efficiently while producing clean cuts regardless of whether the wood is light or heavy duty. Most experienced woodworkers know that matching the tool to the material saves time and money in the long run.

Evaluating Efficiency and Capacity

Looking at a multi rip saw means paying close attention to how efficient it runs and what kind of workload it can manage. The amount of material that needs processing matters a lot because these machines really boost productivity compared to older methods. Take wood cutting for example multi rip saws slice through stock at speeds way beyond what traditional band saws can achieve. Most shops report handling around 20 to 30 square meters per day depending on setup and material type. For businesses dealing with square logs specifically, getting the right balance between cutting speed and capacity makes all the difference. When the machine keeps pace with daily requirements, the whole operation flows smoothly without bottlenecks or wasted time.

To really understand what makes multi rip saws so efficient, it helps to know how they work. These machines have several saw blades arranged in ways that improve cutting accuracy. Some models come with pretty sophisticated blade setups and feeding systems too. Most of the time, the blades travel along a straight line during operation, which helps cut materials better and reduces waste from the wood being processed. When manufacturers arrange these blades strategically and incorporate good feed systems like track type transmissions for smoother material movement, the result is significantly improved cutting performance. This means the saws handle everything from small shop jobs right up to big industrial production needs across different types of woodworking projects. Choosing the right features when purchasing one of these machines allows shops to get more done throughout the day without compromising on either worker safety or the quality of finished products.

Safety and Maintenance Practices

Keeping workers safe when they're operating a multi rip saw should always come first. The basics start with proper gear - everyone needs those safety glasses and thick gloves to avoid getting hurt. Know where those emergency stop buttons are located too, and make sure the blade guard stays in place at all times. Accidents happen fast, so familiarity with these safety measures can make all the difference. Companies shouldn't just train their staff once and forget about it either. Regular refreshers on how to operate the machine safely, plus staying up to date with whatever new safety rules get introduced, helps keep the workshop accident free. A few extra minutes spent on training now can save hours of trouble later down the line.

Maintenance matters a lot when it comes to getting the most out of those multi rip saw machines. When doing routine checks, operators need to look at blade condition and make sure everything is properly aligned so cuts come out right every time. Sharp blades that are correctly positioned do more than just cut better they actually help prolong how long the whole machine will last before needing replacement. Don't forget about lubricating all those moving parts too, plus giving the electrical connections a good once over during these checks. This helps avoid breakdowns down the road and saves money on expensive fixes later on. Companies that stick with regular maintenance schedules tend to see higher productivity rates while protecting what they've invested in their workshop equipment over time.

Final Considerations When Choosing Your Multi Rip Saw

Picking out a multi rip saw? User friendliness matters just as much as someone's skill level with the tool. Machines that are intuitively designed cut down on training time quite a bit and also help prevent those annoying operation errors that slow things down. Good interfaces make all the difference too. When controls are straightforward and clearly marked, operators get up to speed faster. They can run the machine pretty much on their own once they know what they're doing. This means less need for constant supervision from supervisors or managers. The result? Higher productivity across the board while keeping equipment running smoothly instead of sitting idle because someone messed up a setting.

Looking at the price tag versus what a multi rip saw actually delivers is something every buyer should do before making a purchase. Sure, these machines come with a pretty hefty price when bought new, but think about all those hours saved on cutting operations down the road. The right model will crank out more boards per day while maintaining consistent quality cuts throughout. Most shops find that within six months to a year, the extra money spent upfront gets paid back many times over through increased production capacity and reduced labor costs. Some woodworkers even report being able to take on bigger projects they couldn't handle before because of this equipment upgrade.

Safety and Maintenance Practices

Ensuring safety and conducting regular maintenance are fundamental when operating a multi rip saw machine. Operators should always adhere to essential safety precautions, such as using personal protective equipment (PPE) to prevent accidents. Understanding the machine's safety features and functions is equally important to safeguard against operational hazards.

Keeping a multi rip saw running smoothly requires consistent care over time. Checking things like blades condition and making sure everything stays aligned properly goes a long way toward getting good results from this kind of machinery. When operators stick to their maintenance schedule, they often catch small problems before they turn into bigger headaches down the road. The extra effort pays off in longer equipment life too. Beyond just keeping things working right, proper maintenance actually makes the shop safer for everyone around it. A well maintained machine simply poses fewer risks during operation than one that's been neglected.

FAQ

What is the main advantage of using a multi rip saw machine?

The main advantage of using a multi rip saw machine is its ability to enhance productivity by processing large volumes of wood with precision and speed, offering multiple simultaneous cuts that exceed the capabilities of single-blade saws.

How do I choose the right multi rip saw for my needs?

To choose the right multi rip saw, consider the size and dimensions of the timber you regularly process, as well as the type of material (softwood or hardwood) you work with. Ensure the machine's capacity and specifications align with your production demands.

What safety measures are important when operating a multi rip saw?

Important safety measures when operating a multi rip saw include wearing personal protective equipment such as safety glasses and gloves, understanding the machine's safety features, and receiving regular training on machine use and safety protocols.

How often should maintenance be performed on a multi rip saw?

Regular maintenance should be performed periodically, including routine inspections of blade condition, alignment checks, lubrication of moving parts, and electrical connection checks to ensure optimal performance and extend the machine's lifespan.