Understanding Multi-Blade Saw Equipment for Boards

The multi blade saw is pretty much a must have for anyone serious about woodworking. These machines cut boards with amazing precision and get the job done faster than most other tools around. Let's break down what makes them tick. At their core they have those spinning blades that do all the actual cutting work. Then there's the arbor part that keeps everything aligned while it spins. And of course we need some kind of power source to keep things moving along. All these bits fit together so the whole thing can slice right through wood without any hiccups. Most often you'll find these big saws running non stop in sawmills or factory settings where they need to crank out hundreds of pieces every day with razor sharp accuracy.

Getting the right multi blade saw setup matters a lot when it comes to getting things done efficiently while keeping workers safe and producing good quality wood products. When shops have proper equipment, they tend to generate less scrap material, spend less time waiting for machines to fix themselves, and generally keep output levels steady. A properly matched cutting tool makes all the difference too. It cuts down on accident risks during operation and delivers those clean straight lines that customers expect. For woodworkers who want consistent results day after day, spending money on the right kind of multi blade saw system that fits exactly what they need isn't just smart business it's practically essential these days in competitive markets where precision counts.

Key Factors to Consider When Choosing Multi-Blade Saw Equipment for Boards

Choosing the right multi blade saw equipment for working with boards means knowing what options exist and how they actually perform in real situations. The market offers quite a range from standard panel saws all the way to specialty tools such as the Wood Block Multi Blade Saw which handles specific jobs better than others. Panel saws work great when dealing with big sheets of material because they cut straight lines accurately across surfaces. Rip saws take a different approach entirely by slicing wood along its natural grain direction, something especially useful when processing raw timber stock. No two saws do exactly the same thing though, so getting familiar with these differences makes all the difference between good results and wasted time on the wrong tool for the job at hand.

When looking at multi-blade saw specs, things like blade size, motor strength, and how deep it can cut really matter for overall performance. Bigger blades just make sense when working with thicker stock since they can handle those deeper cuts without breaking a sweat. Motor power makes all the difference too, particularly when tackling tough woods like oak or maple. Who wants their saw bogging down halfway through a cut? The cutting depth spec tells manufacturers exactly what kind of material thicknesses their machines can handle day in and day out. All these factors together basically define what kind of work a particular saw can do, and how good it will be at doing it consistently across different projects.

What kind of wood we're working with really matters when picking out multi blade saws for the job. Hardwoods are generally denser and tougher stuff, so they call for heavier duty machines and sometimes require adjustments because of all those different grain patterns and varying moisture levels. Softwoods aren't as hard to cut through, though there are still some things to watch out for depending on what exactly we're dealing with. Getting the right setup for each wood type makes a big difference in how well everything runs and how long our equipment lasts. Machines don't get worn down as fast this way, plus we can keep up good quality output throughout production runs.

How to Choose Multi-Blade Saw Equipment for Boards

Selecting the right multi-blade saw equipment for boards can greatly enhance efficiency and precision in woodworking projects. Here's a step-by-step guide to help you make an informed decision:

Figure out what you actually need first. Take some time to look at what kind of work is coming up for your projects. How much material are we talking about? What thickness do the cuts have to be? And what sort of wood will be involved? Let's face it, someone tackling big projects with heavy timber needs gear that can keep up without breaking down every other minute. The right tools make all the difference when dealing with tough materials over extended periods.

2. Compare Different Models: Utilize comparison charts to evaluate various models. These charts should include details on pricing, features, and user reviews. By doing so, you can easily determine which models offer the best value and meet your project needs most effectively.

3. Consult Industry Experts: Reach out to industry experts or vendors for their insights on the latest multi-blade saw technologies. They can provide valuable advice on ensuring compatibility with your existing tools and recommend models that fit your workspace constraints.

By following these steps, you can effectively choose a multi-blade saw that enhances your workflow and delivers superior results.

Product Recommendations for Multi-Blade Saw Equipment

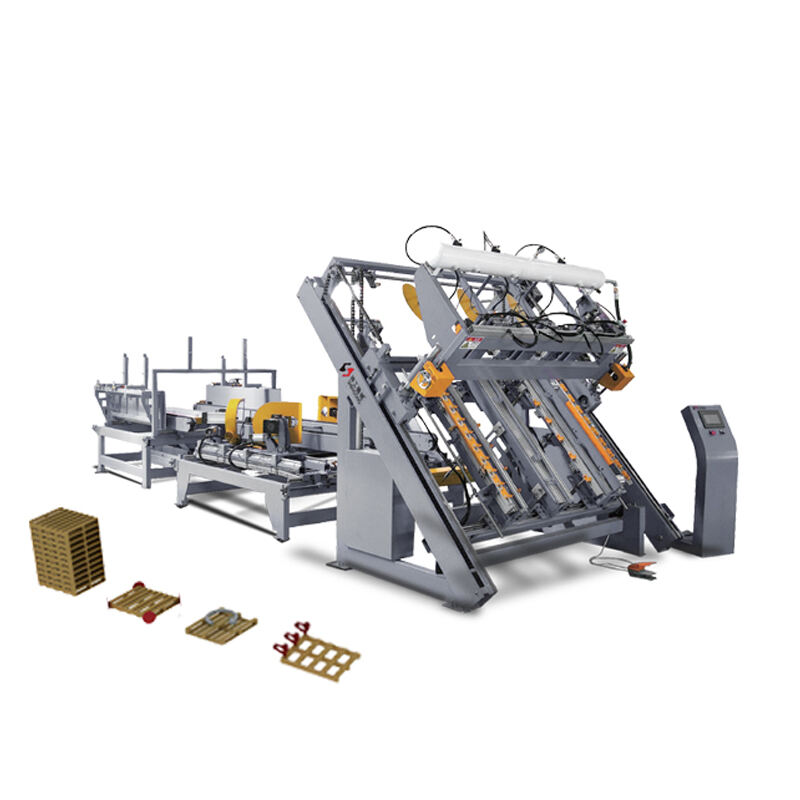

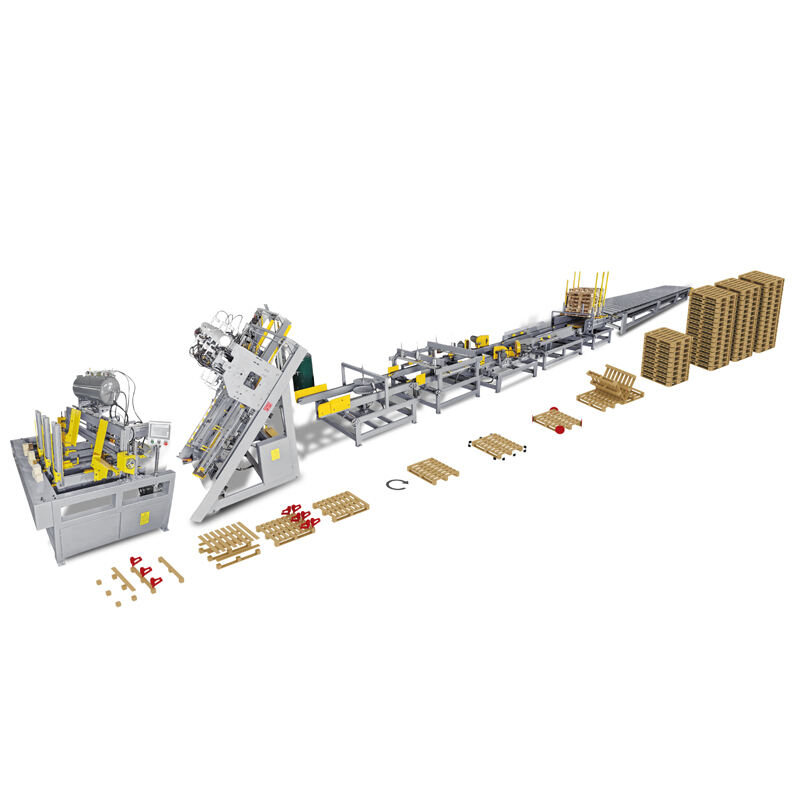

The Wood Block Multi-Blade Saw stands out as a top choice for anyone working with wood materials, offering both speed and flexibility in operation. Designed mainly for making those foot piers that are so important for European wooden pallet construction, this machine also handles square cuts and block work without breaking a sweat. Packing around 30kW of power, capable of slicing through widths up to 200mm, and featuring blades measuring 355mm across, the results tend to be pretty accurate most of the time. What really makes this saw shine though is its automatic cutting feature which lets one person run the whole operation safely while keeping downtime low. For shops looking to cut down on staffing expenses without sacrificing output quality, this kind of setup can make all the difference in daily operations.

Maintaining Your Multi-Blade Saw Equipment

Keeping a multi-blade saw well maintained isn't just good practice it's pretty much necessary if someone wants their tool to last longer and work properly when doing wood projects. The main things people should do regularly are cleaning off all the dust and bits that build up around the blades since this stuff really does affect how the saw performs. Lubricating the moving parts helps everything slide smoothly without grinding against each other, which saves wear and tear over time. And don't forget about sharpening those blades periodically either because dull blades make cuts rougher than they need to be. When woodworkers stick to these basic maintenance steps, they find their machines run better overall while avoiding unexpected breakdowns that stop work cold during important projects.

Recognizing when equipment starts showing signs of wear matters a lot if we want to keep things running safely. When something starts making odd sounds while working, cuts aren't as precise anymore, or there's obvious damage on blades and other parts, that usually means replacement time is coming up soon. Keeping an eye out for these warning signals helps maintain both safety standards and work accuracy in wood projects. This attention prevents potential mishaps at the workshop and ensures whatever gets made turns out looking good enough to be proud of.

Common Mistakes to Avoid When Choosing Multi-Blade Saw Equipment for Boards

Looking at multi blade saws and only thinking about the price tag is probably one of those mistakes people regret later. Sure money matters, but good quality usually means these machines last longer and work better over time. Most folks forget about checking what other users have actually said about their experiences with similar equipment. Real world feedback tends to show problems that aren't mentioned in product descriptions, plus it reveals how well something really performs day after day in actual workshop conditions. Manufacturer specs will tell part of the story, but hands on reports from people who've used them for months give a much clearer picture when trying to pick the right tool for the job.

Maintaining Your Multi-Blade Saw Equipment

Keeping your multi blade saw properly maintained isn't just good practice, it's essential if you want this tool to last through many projects while staying safe to operate. After each use, give the saw a quick clean to stop dust from building up inside where it can cause problems later on. Don't forget to apply some quality lubricant to all those moving parts so everything keeps running smoothly without unnecessary friction. And let's talk about blade sharpness - dull blades are dangerous and produce poor results, so regular sharpening should be part of every maintenance routine. When strange noises start coming from the machine or when cuts aren't as clean as they used to be, that means replacement time for things like blades or drive belts is probably approaching. Pay attention to these warning signs and address them before small issues turn into major headaches down the road. A well maintained saw makes all the difference between frustration and satisfaction at the workbench.

FAQ Section

What are the key components of multi-blade saw equipment?

The key components include saw blades, the arbor, and the power source. These parts work together to ensure smooth and accurate cutting.

How do I choose the right multi-blade saw for my needs?

Assess your project needs, compare different models based on specifications and reviews, and consult with industry experts to ensure compatibility with your current tools and know workspace limitations.

What are the maintenance practices for multi-blade saw equipment?

Routine cleaning, lubrication, and sharpening of blades are essential. Monitoring for signs of wear and replacing components when necessary are also crucial for optimal performance.

Why is it important to consider the type of wood being processed?

Different types of wood, like hardwood and softwood, have specific cutting requirements that can impact equipment selection and performance.