Common Problems in Wood Processing

Spotting problems in wood before processing makes all the difference when it comes to producing good quality finished products. The main issues we see are knots, splits, and warping, though they impact timber in different ways. Take knots for example these happen where branches grew and according to research from the Forestry Commission, around a quarter of softwood contains them. While knots definitely weaken the wood structurally, many people actually find them quite attractive in furniture pieces. When wood dries too quickly, splits start to form and this really takes a toll on strength. Water damage causes another problem called warping, which bends the wood out of shape and basically makes it useless for most applications. Manufacturers need to watch out for all these flaws during inspection processes.

Too much moisture causes all sorts of problems in wood processing. When wood gets damp, it doesn't just grow mold either it warps, cracks, and generally becomes unstable in size. The folks at USDA Forest Service recommend keeping indoor wood somewhere between 6% and 8% moisture content. For outdoor applications where wood faces more weather extremes, they suggest maintaining around 9% to 14%. Getting these numbers right matters because otherwise we end up with warped floors, doors that won't close properly, or furniture that breaks apart after just a few years instead of lasting decades.

In the wood industry, problems during processing remain a persistent issue. Things like misaligned saw blades or setting the feed rate wrong cause all sorts of headaches. When these things happen, they create tons of wasted material and slow down operations across the board. Looking at actual data from mill operators, we see that mistakes in processing cut production output somewhere around 15% in many cases. This kind of loss really highlights why getting those machines properly calibrated matters so much. Skilled workers who know their stuff make all the difference when it comes to avoiding these costly errors.

Tool maintenance remains a big issue for many shops. Keeping machines properly maintained makes all the difference between smooth operations and expensive errors down the line. Take those cutting tools for instance saw blades that get dull from lack of care will start producing inferior cuts, which means more material waste and subpar finished goods. The truth is well maintained equipment runs better day after day while neglected tools wear out faster. Most shop owners know this already but still find themselves replacing tools too often because regular servicing gets pushed aside during busy periods. A little attention goes a long way when it comes to preserving both tool life and bottom line profits.

Solutions for Wood Processing Challenges

Wood processing problems often start right at the beginning with how lumber gets graded and sorted. When companies follow something like the NHLA grading system, they end up with fewer defects and better overall quality in their products. The system looks at all sorts of features in the wood including knots, splits, and other imperfections before putting it into different categories. This makes it easier to pick out the right kind of wood for what needs to be built. Sticking to these standards isn't just about meeting regulations either. Real woodworkers know that following proper grading practices actually saves money in the long run by cutting down on wasted material and返工 costs.

Getting the drying process right makes all the difference when dealing with moisture problems in wood processing. Woodworkers use different approaches like kiln drying and air drying to bring down the moisture levels inside the wood, which stops mold from growing and prevents those annoying warps and cracks. The thing is, not all woods behave the same way during drying. Hardwoods generally take much longer to dry properly compared to softwoods because of their denser structure. Oak might need several months while pine could be ready in weeks. When done properly though, these drying techniques lead to stronger, more reliable finished products that stand up better over time without falling apart at the seams.

Good quality tools really matter when it comes to getting accurate results in woodworking projects. Spending money on dependable machinery cuts down on mistakes and gets things done faster overall. For anyone serious about their craft, durability should be at the top of the list when picking out new gear. Also important are tools that measure accurately and feel comfortable to work with over long periods. Some well known manufacturers produce equipment that lasts years without breaking down, which means fewer interruptions while working on those intricate wood pieces. Of course, these premium options usually come with higher price tags, but many woodworkers find they're worth every penny in the long run.

Keeping tools and machines well maintained is key if we want them to last longer and work at their best. Most shops have some sort of routine that covers basic stuff like wiping down equipment after each job, looking out for signs of damage or wear, and making sure all the moving parts get properly lubricated. Skipping these simple steps can lead to expensive fixes later on and plenty of frustrating stoppages during production runs. For woodworkers especially, regular care makes a real difference in both product quality and how consistently things get made from one batch to the next. The shop foreman at our facility always says that spending 15 minutes daily on maintenance saves hours of headaches down the road.

Effective Tools for Wood Processing

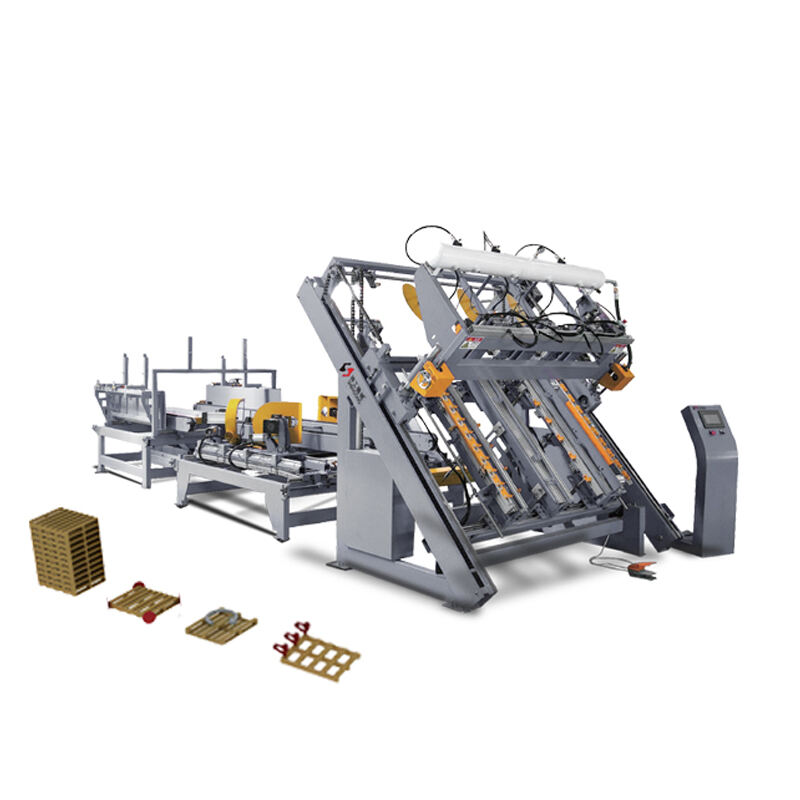

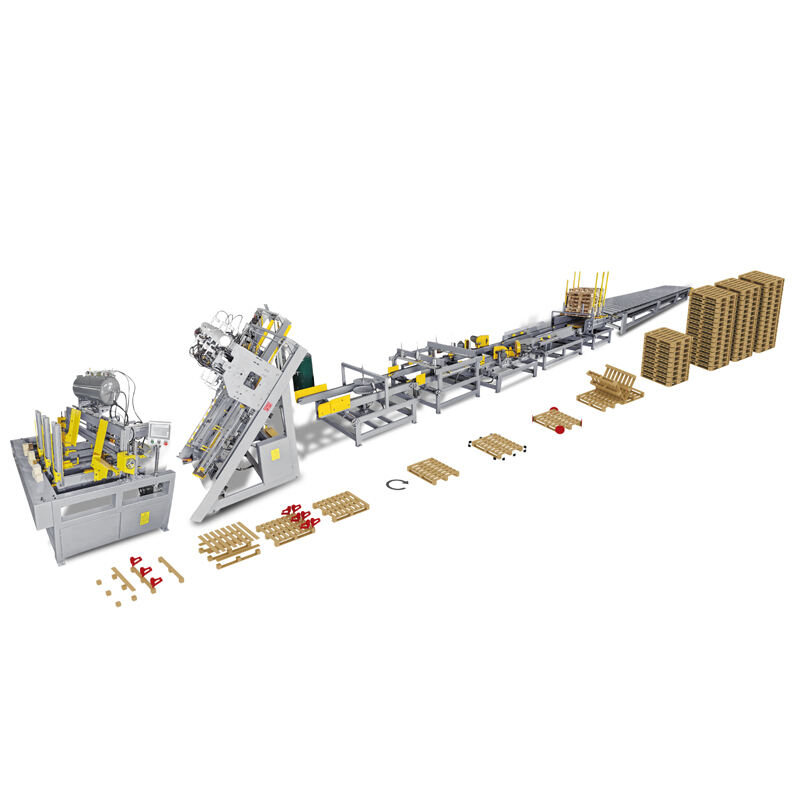

The Wood Pallet Corner Cutter stands out as a game changer in the world of pallet production. What does it do? Simple really cuts those pesky corners off wooden pallets with remarkable precision. The machine itself is built tough enough to handle whatever comes its way on the factory floor. Most setups find it fits right in without needing major modifications. And here's what makes it special works automatically across a wide range of pallet sizes, anywhere between 800mm all the way up to 1300mm. For companies that deal with different pallet specifications day after day, this kind of flexibility saves time and money while keeping quality consistent throughout their operations.

What makes the Wood Pallet Corner Cutter stand out? Well, it comes packed with several special features that really boost what it can do. Safety is built right into the design, so workers stay protected during operation. And because the cutting angles adjust easily, the machine works well with all sorts of wood dimensions. People who have used this cutter frequently mention how straightforward it is to operate and how dependable it proves over time. They also point out that it cuts down on manual work and speeds things up considerably. Industry professionals praise the solid build quality and accurate cutting capabilities, factors that lead to better results when processing wood materials. For anyone running a wood processing business, getting their hands on one of these efficient machines means noticeably better product quality and faster turnaround times without compromising on standards.

Understanding Wood Processing Techniques

Knowing different ways to cut wood makes all the difference when working on specific projects. Rip saws work best when going with the grain, great for those long straight cuts needed in many woodworking jobs. Then there's crosscut saws that slice across the grain instead, giving cleaner ends without splintering too much. Band saws stand out because they can handle so many different woods and create detailed shapes and curves that other saws just cant manage. Picking the right tool matters a lot depending on what needs to get done, and getting this right saves time and frustration in the workshop.

Drying and milling play a big role in improving wood quality while cutting down on defects during production. When done right, methods like air drying or kiln drying stop problems like warping and cracking from happening later on. Getting moisture levels just right in the lumber makes all the difference in what comes out at the end. The milling process itself takes logs and turns them into something useful, but it needs careful handling so the wood stays strong and doesn't get damaged. Taking time to understand how these steps work together actually leads to better results overall. Wood products made with attention to detail tend to last longer and look nicer too, which is why many manufacturers focus so much on getting these basics right first.

After cutting the wood to size, various finishing techniques turn it into something both strong and attractive. Sanding comes next, which involves going over every inch until all rough spots disappear and the surface feels smooth to touch. Many woodworkers apply stain afterward too. This gives the grain a deeper look with colors ranging from warm browns to dark blacks, making the wood stand out while adding another layer of defense against damage. The whole finishing process matters quite a bit because these steps make the wood look better for longer periods. Without proper care, moisture, scratches, and sunlight can wreck even the finest pieces over time.

Preventative Measures to Enhance Wood Quality

Getting top quality results from wood processing starts with picking out good raw materials first. The type of wood we source really affects how everything turns out in the end, from the look of finished items to how they hold up over time. Most folks in the business know this already. There are actually quite a few industry guidelines available if someone wants to check them out. Organizations such as the USDA Forest Service have developed standards that can point people toward better choices when looking for wood that fits particular requirements. These standards aren't just rules on paper either they represent years of experience figuring out what works best for different applications across the woodworking industry.

Proper storage of wood is also crucial in maintaining its quality. By controlling humidity levels and avoiding direct sunlight, the risk of wood defects such as warping or cracking is minimized. This ensures the wood remains stable and ready for further processing.

Wood gets damaged by all sorts of environmental stuff like heat changes, moisture levels going up and down, plus bugs getting into it over time. People dealing with wood products need to fight back against this damage. Applying special coatings that keep pests away works pretty well, along with keeping materials stored somewhere where temperature stays fairly constant. Some folks swear by borate treatments for insect protection while others prefer oil-based finishes. The real trick though is checking on things regularly and making small adjustments when needed. This kind of hands-on approach helps maintain good quality throughout the whole manufacturing process from raw material to finished product.

FAQ

What are common defects in wood processing?

Common defects in wood include knots, splits, and warping, which can affect structural integrity and usability.

How does moisture affect wood processing?

Excess moisture can lead to mold growth, dimensional instability, and potential defects in wood products.

Why is tool maintenance important in wood processing?

Regular tool maintenance enhances efficiency, prolongs equipment lifespan, reduces waste, and improves product quality.

What are effective drying techniques for wood?

Effective drying techniques include kiln and air drying, tailored to specific wood species for optimal results.