Understanding Wooden Pallet Production Line Automation Trends

In wooden pallet manufacturing, automation has become essential for boosting both productivity and worker safety across the board. When factories install automated equipment, they typically see faster production times, lower payroll expenses, and fewer mistakes that happen when humans get tired or distracted. The biggest benefit? Every pallet comes out looking pretty much the same, which matters a lot when clients need thousands of identical units. Plus, machines don't waste raw materials like people sometimes do. Many plants are struggling to keep up with orders these days, so having consistent output makes all the difference. Take AGVs for instance these little driverless carts zip around warehouses moving heavy loads from one station to another without breaking a sweat. They just keep going day after day, rain or shine, making sure nothing gets stuck in the workflow.

Automation is changing everything in the wooden pallet industry, moving away from those old manual methods that used to dominate the sector. Back in the day, making pallets was all hands-on work, lots of repetitive motions and constant risk of injury for workers who spent hours stacking wood and nailing pieces together. Now things look completely different thanks to tech innovations like smart LiDAR sensors paired with industrial robots. We've seen some real game changers lately too, especially with the rollout of vision guided transport systems and autonomous mobile robots around warehouses. These machines handle materials much better than humans ever could, reducing errors while keeping folks out of dangerous situations. The whole industry keeps finding new ways to integrate cutting edge tech into their operations because at the end of the day, nobody wants wasted time or preventable accidents when producing millions of pallets every month.

Current Trends in Wooden Pallet Production Line Automation

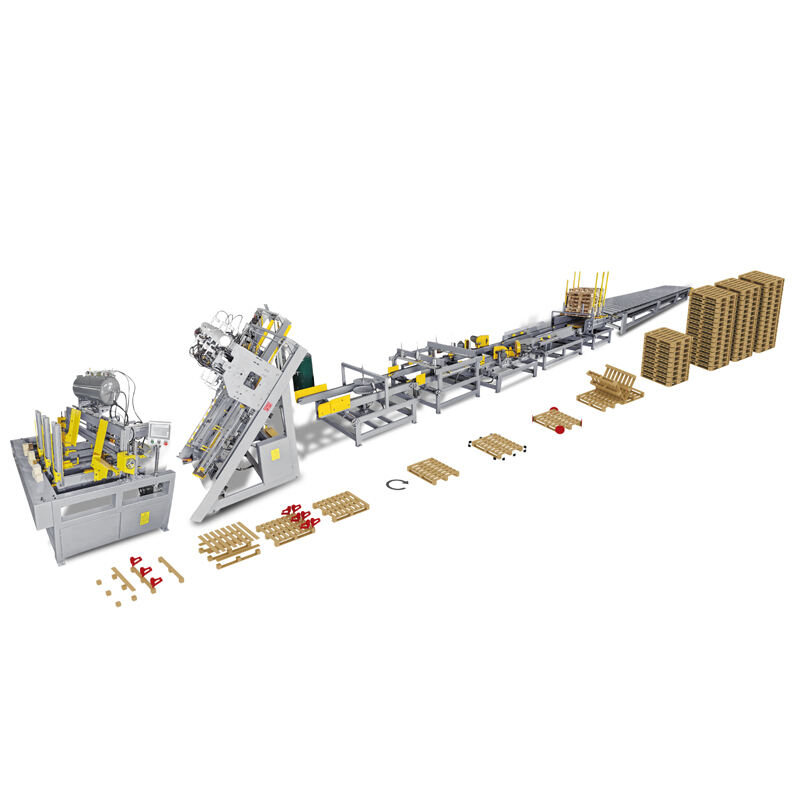

Wooden pallet production lines now rely heavily on robotics for faster and more accurate work across assembly, stacking operations, and quality inspection processes. These machines take over the repetitive jobs that used to require lots of manual labor from workers standing on factory floors all day long. Modern robotic systems come with built-in cameras and various sensors that help them put together each pallet component with remarkable accuracy. Mistakes get caught early and overall product quality stays consistent even when production volumes go up. Manufacturers report they can handle bigger orders without sacrificing their usual quality standards thanks to these automated solutions.

The wood pallet manufacturing sector is undergoing quite a transformation thanks to IoT and smart tech integration on production floors. With sensors and connected devices now part of daily operations, plant managers get instant visibility into what's happening across their facilities. This real time data gives them actionable information that helps fine tune how things run day to day. Take material tracking for instance smart sensors keep tabs on where everything is at all times, which cuts down on those frustrating production stoppages we've all seen happen too often. Beyond just making operations run smoother, these systems let manufacturers spot potential equipment issues before they become major problems. Machines break down less frequently and when they do, everyone knows exactly what went wrong. We're seeing this trend accelerate as more businesses realize how much better organized their production can be. Wooden pallet makers who embrace these tools find themselves far more responsive when market demands shift unexpectedly.

Benefits of Automation in Wooden Pallet Production Line

Wooden pallet production has gotten a major boost from automation technology. The numbers tell the story pretty clearly industry data shows manufacturing times drop around 25-30% when plants go automated. What makes this possible? Machines like the wood pallet stacker handle repetitive tasks that used to take hours of manual labor. Take a look at any modern pallet factory floor these days and you'll see workers freed up from lifting heavy loads all day long. Companies are able to crank out twice as many pallets without adding extra staff, which matters a lot given how much the logistics sector needs them right now. Shipping companies especially rely on this increased throughput during peak seasons when demand spikes unexpectedly.

Automation cuts down on operating costs, so it makes financial sense for many businesses. Companies that bring in automated systems usually need far fewer staff members for jobs such as sorting materials or stacking items something that used to take a lot of manpower. Take wooden pallet manufacturing for instance some firms report cutting labor costs by around 20 after going fully automated. Lower expenses mean money saved, and those savings can go toward other areas where companies might need extra support. This gives them an advantage over competitors who haven't made similar investments in technology yet.

Challenges Facing Wooden Pallet Production Line Automation

Getting wooden pallet production lines automated comes with some pretty big hurdles, mainly because of how much money it takes upfront plus all those ongoing expenses for running new tech. When manufacturers switch from hands-on work to machines doing the job, they need to shell out cash for expensive equipment like pallet stackers and conveyor belts that require constant maintenance too. And let's not forget about keeping everything updated over time so it meets current industry requirements. Even though saving money on wages down the road sounds great in theory, many smaller operations just don't have access to enough capital to cover these initial investments. For family owned businesses or local manufacturers without deep pockets, this makes adopting automation seem almost impossible at times.

Beyond money issues, bringing automation into the pallet business means having workers who know how to run these fancy machines. Training becomes a real headache because existing staff need to learn completely new skill sets just to handle automated equipment properly. Some research from the Journal of Manufacturing Technology Management points out that keeping workers educated is pretty much essential if companies want their automation efforts to actually work on production floors. While good training programs and learning materials definitely help, many businesses still struggle when trying to move toward tech-based operations. There's no magic bullet here, but investing time in employee development remains critical for long term success in this changing landscape.

Case Studies of Successful Wooden Pallet Automation

A number of businesses have started using automation on their wooden pallet production lines, showing some pretty impressive tech improvements along the way. Take PalletOne for example they're one of the big names in this industry and they've rolled out around 140 automated machines throughout their different locations. What these companies are doing goes beyond just robots working the line. The whole system runs much smoother now, with production speeds jumping somewhere around eight times what competitors can manage. This kind of boost makes a real difference in how competitive these manufacturers stay in the market.

Bringing these automation approaches into play has really paid off for manufacturers across the board. Production lines are running smoother, there's way less material going to waste, and quality checks have gotten much tighter. Looking at numbers from PalletOne, they saw something like 30% less waste overall while their output shot up by almost the same amount. That kind of boost makes all the difference when trying to keep up with what customers want these days. Industry pros who've made the switch talk about how these tech upgrades give them an edge over competitors still stuck in old ways. Their teams can pivot faster between different product runs and respond to last minute changes without breaking a sweat.

Niagara Pallet offers yet another great look at what automation can do for businesses. When they installed the IVISYS PALLETAI inspection system, their output per worker basically doubled overnight. The company now gets twice as much done without needing extra staff, which shows just how much better tech makes things run smoothly while keeping quality checks consistent. Looking at real world examples like this helps explain why so many manufacturers are jumping on the automation bandwagon these days. Traditional ways of making wooden pallets just cant keep up with what customers want anymore, especially when it comes to speed and reliability requirements in modern supply chains.

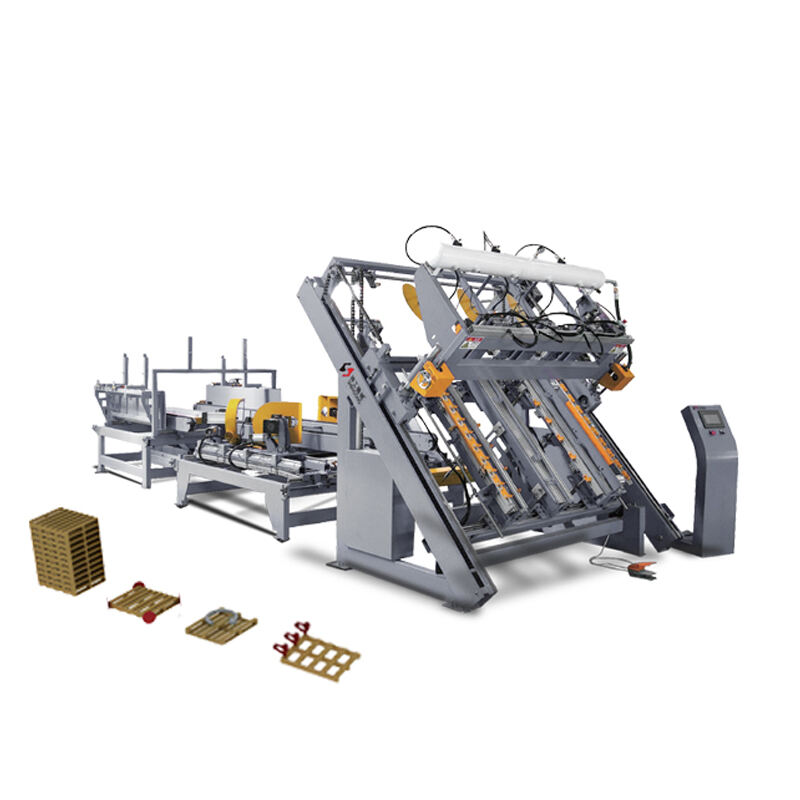

Key Products Enhancing Automation in Wooden Pallet Production

The Wooden Pallet CNC Cutting Saw stands out as a game changer in automated wooden pallet manufacturing. What makes this machine so special? It cuts wood with incredible accuracy compared to older methods, saving time and money on the production line. The saw works with all sorts of lumber types, slicing them down to exact measurements needed for pallet construction. This means less scrap wood going to waste and better use of raw materials overall. Plus, operators can tweak the machine's settings to tackle complicated cuts that would be tough with standard equipment. For small shops and large factories alike, this kind of adaptability makes a real difference when meeting diverse customer orders day after day.

Wooden pallet makers have seen a big boost in how fast they can produce goods since bringing in CNC Cutting Saws. These machines handle the cutting automatically so products get finished much faster than before. Orders don't sit around waiting anymore which means customers get their shipments on time. Another major plus is that there are fewer mistakes compared to when workers did all the cutting by hand. The result? Every pallet comes out looking pretty much the same quality wise, and nothing gets stuck in the production line because someone messed up measurements. For companies dealing with large orders from warehouses and distribution centers across the country, this kind of tech makes all the difference. It helps keep up with what businesses need now - reliable supplies without delays or defects ruining reputations.

FAQ

What are the benefits of automating wooden pallet production?

Automation in wooden pallet production enhances efficiency, reduces labor costs, minimizes errors, and meets increasing demand while maintaining high quality standards.

What are common challenges faced while automating wooden pallet production lines?

Common challenges include high initial investment costs, the need for ongoing maintenance, and the requirement for a skilled workforce to manage advanced machinery.

How does IoT contribute to wooden pallet production line automation?

IoT allows for real-time monitoring and data analysis, optimizing production processes and enabling predictive maintenance which reduces unexpected machine failures.

What are some examples of successful automation in wooden pallet production?

Companies like PalletOne and Niagara Pallet have leveraged automation to enhance productivity and efficiency, demonstrating significant waste reduction and increased production capacity.