Overview of Development Trends in Environmentally Friendly Wood Processing Equipment

More and more people around the world are talking about sustainability these days, and this has put pressure on industries everywhere to find ways to be kinder to the environment. The wood processing sector isn't standing still either, gradually bringing in greener tech solutions to cut down on their ecological impact. This change matters a lot when it comes to fighting climate change and stopping forests from disappearing at such an alarming rate. Take a look at recent improvements in equipment like palletizing machines and those big wood drying kilns we see at mills. These newer models actually consume less power and produce fewer harmful emissions compared to older versions, making them real game changers for companies trying to clean up their operations.

The rules set by agencies like the EPA have become really important for how wood processing machines get designed and built these days. When companies follow these environmental regulations, they actually end up creating better equipment that meets modern sustainability standards. This compliance isn't just about checking boxes though it genuinely makes manufacturing processes work smarter rather than harder. For businesses looking at long term survival, sticking to these regulations means reducing those nasty environmental side effects from old school methods. Plus, it pushes them towards using greener materials across the board. What's interesting to note is that many machine makers find themselves competing on new fronts where being eco friendly matters almost as much as price tags. We're seeing some pretty cool developments too band saws now come with special features, and portable sawmills are getting upgraded with technology that just plain supports greener operations throughout the whole industry.

Innovations in Wood Processing Technology

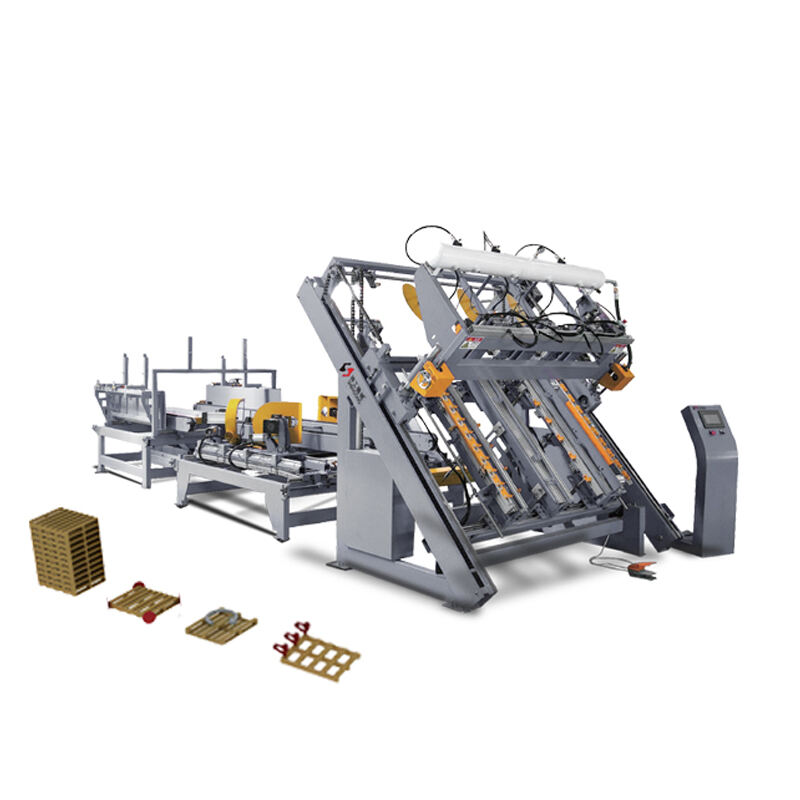

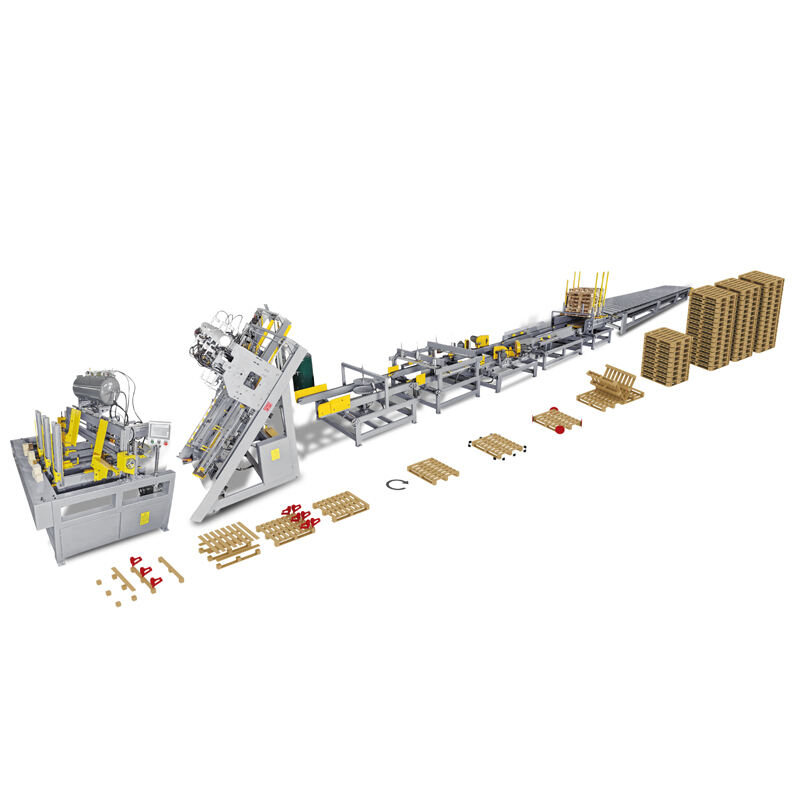

More and more wood processing companies are turning to automation these days, which has really changed how operations run and cut down on wasted materials. Take palletizer machines for instance they allow for much more accurate cuts and assembly work, so less wood gets thrown away during production runs. The bottom line? Companies save money because they're using fewer raw materials overall, and profits go up as a result. What's interesting is that bringing in all this new tech doesn't just boost output numbers it actually fits right into what the industry cares about now sustainability. Many manufacturers see this as a win-win situation where their bottom lines get healthier at the same time they reduce environmental impact.

Green materials are changing how wood processing equipment gets designed these days, sparking new ideas around sustainability. Many manufacturers have started using parts that break down naturally or can be recycled again, so the machines themselves actually help protect the environment. Going green isn't just about following rules anymore it shows companies really care about building an industry that respects nature. These changes matter for the future of wood processing because they cut down on waste while also attracting customers who want to buy from businesses that share their values when it comes to protecting our planet.

Key Features of Modern Environmentally Friendly Wood Processing Equipment

Today's wood processing gear comes packed with tech that cuts down on power usage while keeping emissions low. Some of the newer models slash energy needs around 30% compared to older versions, which means real money saved over time for businesses running them day after day. Plus, there's another benefit nobody talks about much these days but matters a lot: better air inside factories since these machines spew out far fewer harmful stuff when cutting through timber. For companies trying to green up their act across all areas of operation, adopting this kind of equipment isn't just smart business it's becoming something customers actually expect from responsible manufacturers.

Durability and how long these machines last has become really important in the latest developments for wood processing equipment. The new tech being added doesn't just make them last longer, it actually cuts down on how much maintenance they need over time. Take a look at what's happening in the field right now – some manufacturers report around 20% longer life spans for their machines since implementing these upgrades. That means fewer replacements needed and obviously less waste generated from old parts. For businesses running sawmills or furniture factories, maintaining good production rates while keeping environmental footprints small makes perfect sense. When companies focus on making their equipment last longer and run more efficiently, the wood processing sector gets closer to meeting green standards without sacrificing profitability. It's basically winning on two fronts at once.

---

By blending energy-efficient technologies with durable components, manufacturers are poised to lead in sustainable wood processing, setting benchmarks for reduced waste and improved air quality. As the demand for eco-friendly practices rises, these advancements pave the way for a future where profitable production and environmental preservation coexist.

Current Market Trends in Sustainable Wood Processing Equipment

Recyclable and biodegradable equipment is becoming really popular among wood processors these days. Many companies have started changing how they manufacture things so they can hit those green targets customers want when buying eco stuff. The market seems to be moving toward wood processing options where materials can actually get reused or broken down naturally. Some recent surveys show people are getting much more interested in buying products made this way. With everyone talking about climate change and sustainability now, manufacturers feel pressure to develop tools that leave smaller marks on the environment. This push for greener alternatives is definitely pushing the whole industry forward with new sustainable approaches popping up all over the place.

Smart tech is changing how we work with wood these days. Manufacturers are putting IoT and AI into their log cutters and band saws which helps them track materials better and run operations smoother. When companies start using this kind of tech, they find ways to cut down on waste, save money on materials, and get much better results from what they do process. These smart systems let workers watch everything happening right now and make adjustments without stopping production. We're seeing this happen across many woodworking shops actually, as owners try to make their businesses both greener and more profitable at the same time through digital upgrades.

Impact of Development Trends on Industry Practices

We're seeing a clear movement toward green manufacturing across the wood processing sector these days. Companies such as Stora Enso and Metsä Group stand out for their work in renewable energy projects and better forest management practices. These efforts actually demonstrate how businesses can cut down on their environmental footprint without hurting profits at the same time. What's happening here isn't just random experimentation either. The whole industry seems to be following suit because of stricter environmental laws and customers wanting more environmentally friendly options when they shop. Take sustainable forestry methods for example. They help keep ecosystems healthy while making sure there will still be good quality wood available for future production needs.

Switching to sustainable wood processing tech actually saves money in the long run while also tapping into growing market demand. Industry data shows that going green cuts down on both energy use and waste production, which naturally brings down what businesses spend day to day. More people want sustainably made products these days, so there are plenty of fresh opportunities waiting for companies willing to adapt. When manufacturers start using machines like automated palletizers and mobile sawmills, operations get smoother and faster. Plus, promoting real sustainable materials makes sense for business too. Eco-minded shoppers tend to stick with brands that share their values, giving companies an edge over competitors who haven't made the switch yet.

Product Spotlight: Environmentally Friendly Wood Processing Equipment

Wooden pallet branding machines really stand out when it comes to getting things done without wasting energy, which matters a lot for anyone working with wood in an environmentally conscious way. These machines are built tough with good quality metals inside, they don't guzzle electricity and heat up pretty well too. What this means is faster work rates without burning through power or needing extra hands on deck. Perfect setup for bulk manufacturing actually, since operators can tweak how hard the stamps press down, what temperature they run at, and how long each cycle takes. Many green focused businesses have found these adjustments make all the difference in their day to day operations where both saving money and protecting the planet go hand in hand.

FAQ Section

Q: What are some key environmentally friendly technologies in wood processing equipment?

A: Key technologies include energy-efficient machines that save up to 30% power, biodegradable and recyclable components, and smart technologies like IoT and AI for optimizing production.

Q: How do EPA guidelines affect wood processing equipment?

A: EPA guidelines ensure that wood processing machines comply with sustainable standards, promoting more efficient manufacturing processes and the use of sustainable materials.

Q: What economic benefits do sustainable wood processing technologies offer?

A: They reduce energy consumption and waste, thereby lowering operational costs and opening new market opportunities with the rising demand for environmentally-friendly products.