Choosing the Best Band Saw for Small Scale Woodworking

Picking out a band saw for those little woodworking jobs means getting familiar with what's out there and matching it up against what actually gets done at the workbench. Most band saws fall into two main categories these days: vertical models sit upright while horizontal ones lie flat. The vertical kind has become pretty popular among woodworkers because they can handle all sorts of fancy curves and complicated shapes that make sense when working on tiny details or custom furniture parts. Horizontal band saws tend to show up more often in metal shops though some folks do use them for slicing through big slabs of lumber straight across the grain. When shopping around, think about whether precision cuts matter most or if speed becomes important depending on what kind of materials will be going through the machine regularly.

Finding the right band saw starts with knowing what kind of work needs doing in the workshop. Different materials call for different approaches. Woodworkers who spend most of their time slicing through timber might find vertical models better suited for their needs since they're built specifically for handling wood grain properly. Size matters too when picking equipment. Larger workpieces mean bigger throat capacities are necessary, while taller items require sufficient vertical clearance space inside the machine frame. Matching specs to actual workshop demands turns a simple purchase into something far more valuable over time. A well-chosen band saw becomes part of daily routine rather than just another piece of machinery sitting around collecting dust between uses.

Top Recommendations for the Best Band Saws for Small Scale Woodworking

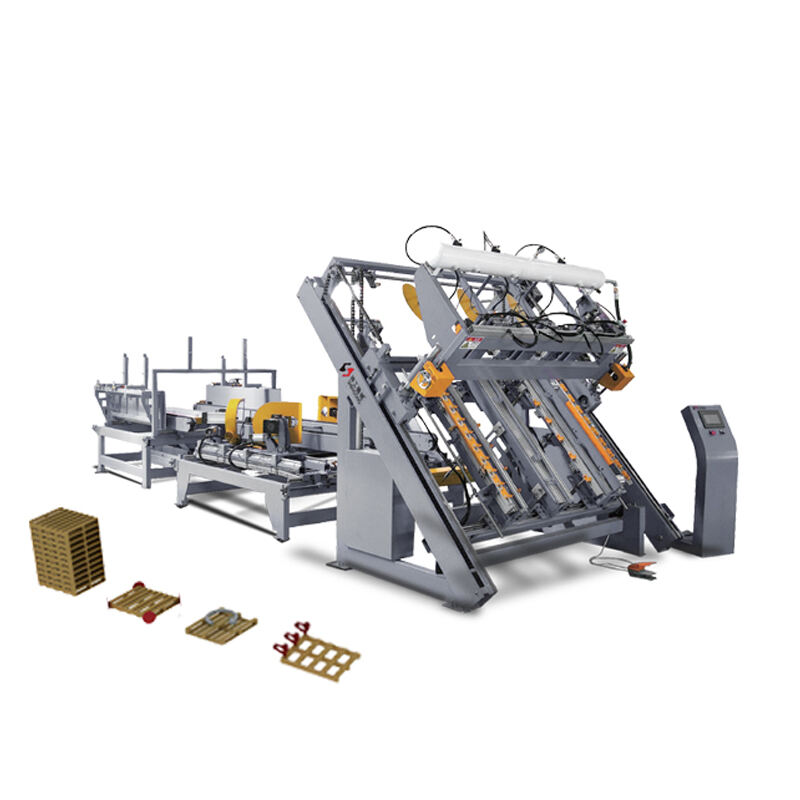

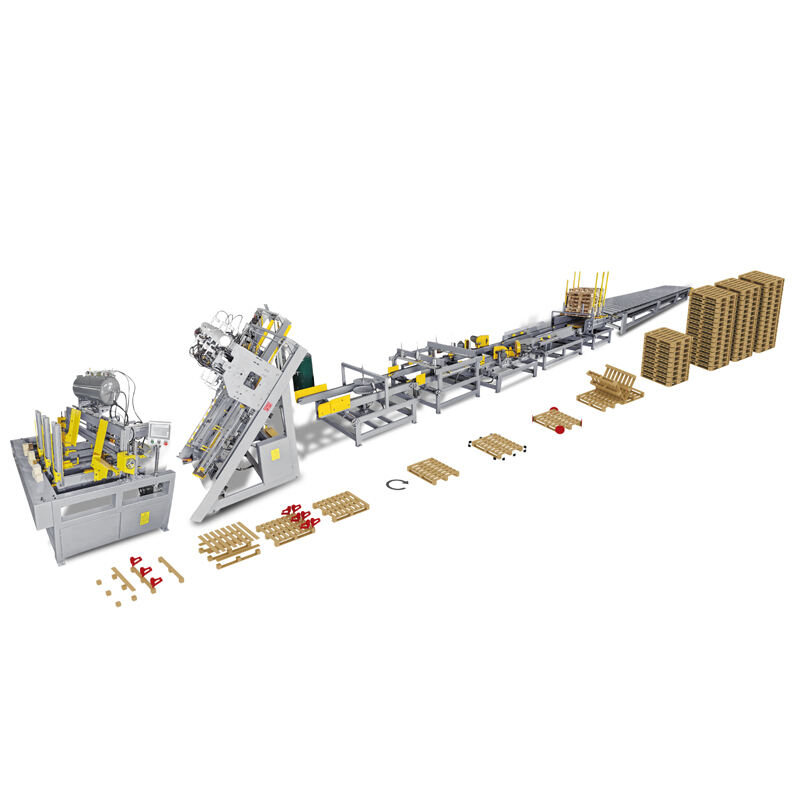

For folks working on smaller woodworking projects around the shop, picking out the correct band saw really matters. The Wood Pallet Machine stands out among other options as something pretty flexible for those who need both speed and versatility in their work. What makes this particular machine so great for smaller shops? Well, it takes all that scrap wood lying around and turns it into solid pallet feet without much hassle. Beyond just saving materials, the end result tends to be quite good quality too. That's why many woodworkers find themselves coming back to this machine again and again when they tackle different kinds of jobs in their workshops.

What really sets the Wood Pallet Machine apart isn't just how fast it works but how precisely it cuts materials. Most woodworkers know that getting clean, accurate cuts matters a lot for quality results, and this machine handles that part without any hassle. Even folks new to woodworking can pick it up pretty quickly thanks to straightforward controls and clear instructions included in the package. Plus, the whole unit packs down small enough to toss into a pickup truck bed when moving between jobsites or simply reorganizing workshop space. This combination of mobility and simplicity makes the machine popular among professional contractors as well as weekend DIY enthusiasts looking to take their projects to the next level without breaking the bank on expensive equipment.

Its operational smoothness, combined with the ability to process a variety of wood types, further cements its place in the woodworking realm. Whether you're crafting detailed pieces or handling larger projects, understanding the capabilities of tools like the Wood Pallet Machine can significantly elevate the outcome of your work.

Key Features to Look For

Choosing the right band saw means knowing what matters most for getting work done efficiently in woodshops. Motor strength and how fast the blade moves really count. Band saws with strong motors plus blades that can change speeds let woodworkers handle all sorts of materials without much hassle. This kind of flexibility makes a big difference when tackling different jobs around the shop. Some folks cut through soft pine one day and dense oak the next, while others might need to work with those tricky composite boards that have become so common lately.

When thinking about what kind of band saw works best, don't forget to check out cutting capacity and blade width too. Small shops especially need machines where the blade size matches their actual workspace limitations. A good rule of thumb is finding equipment that offers just enough throat depth and vertical reach for day-to-day projects around the shop. Getting this right means being able to tackle those tricky curved pieces alongside regular straight cuts while still keeping the finished product looking sharp and professional. Most woodworkers know that getting these measurements wrong leads to frustration later on when trying to complete complex designs.

Material versatility matters a lot when choosing a band saw. Good quality models cut through various materials without breaking a sweat. They switch effortlessly from hardwood to softwood and can tackle composite materials too. When a band saw handles multiple wood types well, it lasts longer and opens up new possibilities for projects around the workshop. Anyone who works with wood knows that being able to get clean, accurate cuts across different materials makes all the difference in completing jobs efficiently and professionally.

Benefits of Using a Band Saw

Utilizing a band saw in small workshops greatly enhances operational efficiency. These machines are designed to execute quicker cuts with precision, significantly reducing material waste and saving time. This efficiency translates into increased productivity, which is pivotal for small-scale operations where time and resources are often limited.

Band saws really stand out because of how versatile they are for different woodworking tasks. They work great on everything from building fancy furniture joints to making those little decorative items people love so much these days. The real magic happens when cutting curves and complicated shapes something most other tools just cant do without a lot of fuss. Woodworkers who want to create one-of-a kind pieces find themselves coming back to the band saw again and again. It handles thick oak as easily as thin maple veneer, which makes it super valuable for anyone serious about expanding their workshop capabilities beyond basic straight cuts.

Maintaining Your Band Saw

Regular maintenance is essential to keep your band saw in peak condition and ensure smooth operation. Here are some routine maintenance tips:

- Blade Changes: Regularly check and change the blade to keep cuts clean and precise. A dull blade can damage materials and increase strain on the motor.

- Cleaning: Keep the machine free from dust and debris. Wipe down the surfaces and clearing out the dust port after each use.

Troubleshooting some basic problems with a band saw saves plenty of headaches down the road. When cuts aren't going straight, most folks forget to look at blade alignment first before blaming everything else. A quick check on tension settings usually reveals where things went wrong. Excessive vibration? That typically means either the blade isn't seated right in those guides or maybe the table just needs leveling out. Most fixes involve nothing fancy - just tightening bolts here and there, adjusting guide blocks correctly. These little tweaks keep machines performing well for years instead of throwing money at new equipment every time something goes sideways.

Safety Tips for Using Band Saws

Safety gear matters a lot when working with band saws if we want to avoid getting hurt. Gloves are a must for protecting hands against those razor sharp edges, while goggles keep dust and bits of material out of our eyes during operation. Getting properly dressed before starting up the machine isn't just good practice it's actually the foundation for staying safe throughout any cutting job.

Wearing proper safety equipment goes hand in hand with good practice when operating a band saw, which makes for safer and more effective results overall. Stand steady with both feet planted firmly on the ground and make sure whatever needs cutting stays securely fastened during operation to avoid accidents from slipping materials. Feed pieces into the blade at a relaxed pace rather than rushing them through, letting the tool handle most of the work instead of forcing it along. Stick with these basic guidelines and operators will find they get better performance from their band saws while staying out of harm's way throughout the process.

FAQ

Q: What type of band saw is best for small-scale woodworking projects?

A: Vertical band saws are typically ideal for small-scale woodworking due to their ability to cut intricate curves and shapes, making them perfect for detailed projects.

Q: How important is motor power in a band saw for woodworking?

A: Motor power is crucial as it affects the cutting capabilities and efficiency of the saw. A more powerful motor with adjustable blade speed is preferred for tackling various materials and projects.

Q: What are some maintenance tips to keep a band saw in good condition?

A: Regularly change the blade to maintain cutting precision, clean the machine to remove dust and debris, and troubleshoot common issues like blade misalignment or tension problems to ensure smooth operation.