Why Energy Efficiency Matters in Modern Timber Processing

These days, timber mills are in a tough spot. They need to keep up with production demands, but they also have to be more environmentally friendly. One big part of this challenge is energy consumption. In a typical sawmill, energy costs can make up anywhere from 25% to 40% of the total operational expenses. That's a huge chunk of change! So, upgrading to more energy-efficient equipment has become a top priority. Advanced sawmill lines are now equipped with smart motor systems. These systems are like having a little brain that can tell the motor how much power to use based on the type of wood being cut and the specific cutting requirements. As a result, they can cut down on energy waste when the machines are idle by up to 35%. Then there are thermal recovery systems, which are truly revolutionary. They capture the extra heat generated by the friction of the saw blades and use it to pre-dry the lumber or power other auxiliary systems. With these kinds of innovations, timber mills can meet the ISO 50001 energy management standards while still processing wood at speeds of over 150 meters per minute, keeping production moving smoothly.

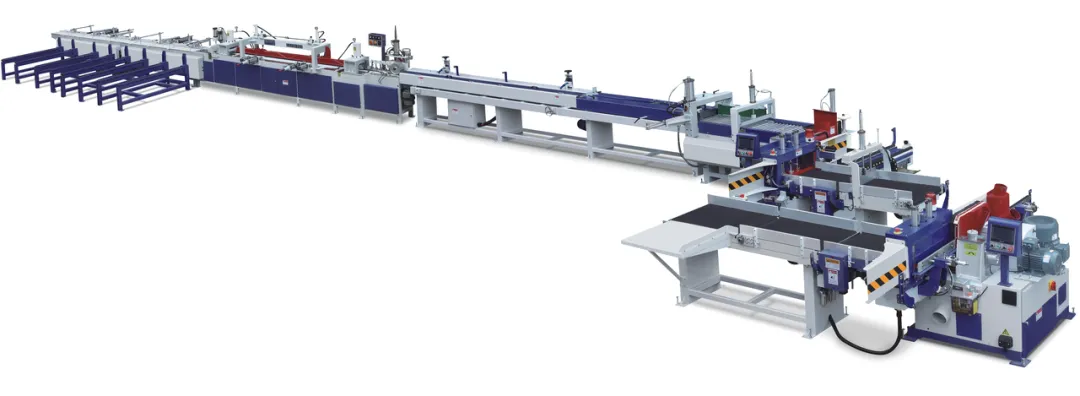

Optimizing Production Through Intelligent Sawmill Design

Making the switch to a more energy-conscious way of processing timber means having equipment that's designed to minimize waste at every step. Modern sawmill lines use laser-guided positioning systems, which are a huge improvement over the old manual alignment methods. These lasers help the machines make the most of each log, increasing the utilization rate by 18 - 22%. That's like getting more bang for your buck with every piece of wood. Automated blade lubrication systems are another great addition. They apply biodegradable coolants at just the right times and in the right amounts. This not only extends the life of the blades by 40% but also uses less fluid, saving money and being better for the environment. When timber mills are looking at different sawmill configurations, those that are thinking ahead opt for modular designs. These designs allow them to upgrade their equipment in stages, without having to stop production. Take finger joint processing technology as an example. It cuts the wood with such precision that it can achieve a 98% material utilization rate, joining boards together seamlessly from end to end. And it does all this while being 30% faster than traditional jointing methods, all the while ensuring the structural integrity needed for high-quality construction lumber.

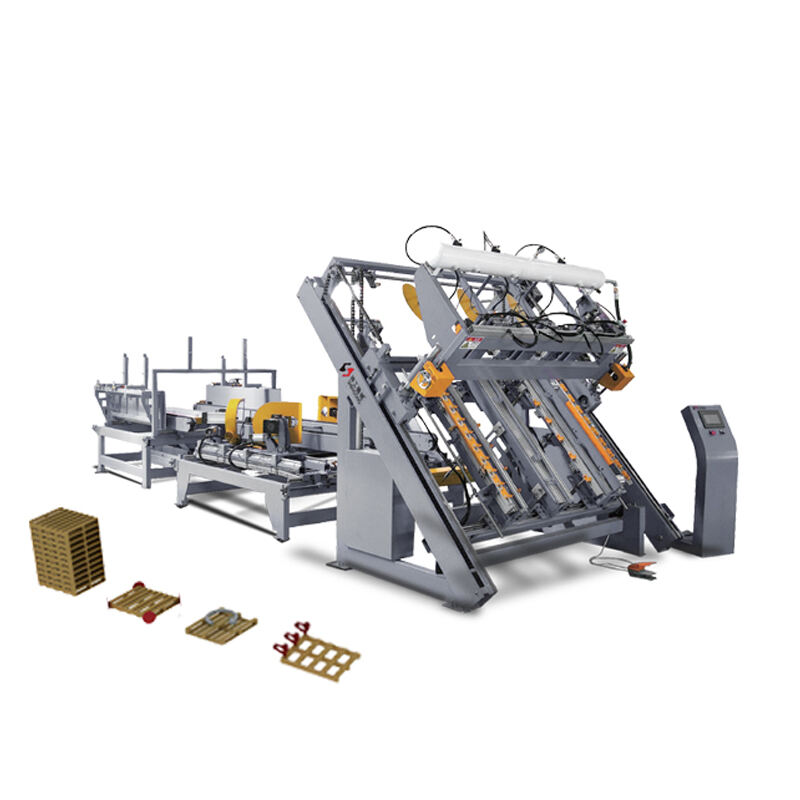

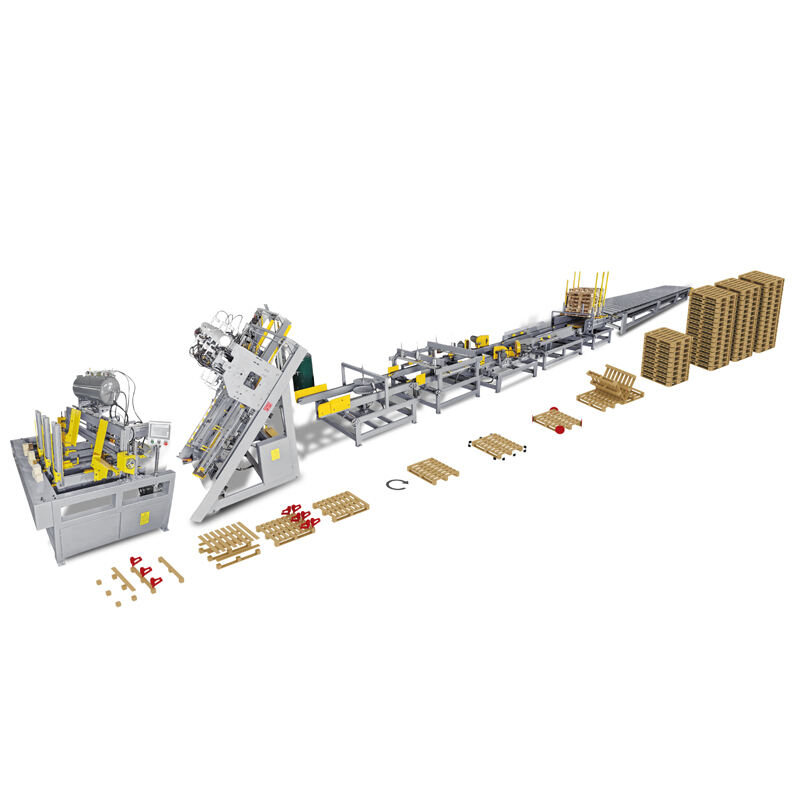

Strategic Approaches to Sustainable Timber Yield Maximization

In a competitive market, getting the most out of every piece of raw timber is crucial for timber mills. Today's sawmill lines are using some pretty amazing technology to do just that. They have real-time AI-powered scanning systems that analyze the shape and structure of each log just 0.2 seconds before it's processed. This allows the machines to automatically adjust the cutting patterns, taking into account things like knots, the direction of the grain, and any natural defects. As a result, they can increase the recovery rate of premium-grade boards by 15 - 20% compared to using fixed cutting templates. Dust management systems have also come a long way. Modern cyclonic separators are so effective that they can capture 99.8% of the particulate matter. Instead of being waste, this dust can be turned into biomass pellets or composite materials, creating an additional revenue stream. And in the treatment facilities, water recycling systems are now able to reuse 90% of the water through a multi-stage filtration process. This not only helps the environment but also cuts down on water and utility costs for the mill.

Future-Proofing Operations Through Adaptive Sawmill Technology

The timber processing industry is constantly changing, and mills need equipment that can adapt. The new generation of sawmill technology focuses on just that. Conveyor systems now have variable-frequency drives, which means they can instantly change their speed anywhere from 0 to 6 m/s. This makes it easy to handle different types of wood and produce various products. Cloud-connected diagnostic modules are like having a team of experts watching over the equipment. They can detect potential problems 72 hours before a component might fail and send out predictive maintenance alerts. This helps reduce unplanned downtime by 85%, keeping the production line running smoothly. In the drying process, hybrid systems combine microwave-assisted heating with traditional convection methods. This innovative approach reduces the energy consumption per board foot by 40% while still ensuring that the moisture content of the wood varies by less than 0.5%. With these technological advancements, timber mills can easily switch between producing standard dimensional lumber and specialty products like finger-jointed structural components, all without having to spend a fortune on retooling.

Enhancing Operational Safety While Cutting Energy Costs

Modern sawmill technology isn't just about saving energy; it's also about keeping workers safe, and these two goals often go hand in hand. Automated emergency braking systems are a prime example. They can stop a 2-ton carriage assembly in just 0.8 seconds, and while doing so, they convert the kinetic energy into electricity that can be reused. This not only protects the workers but also helps save energy. Ergonomic control interfaces are designed with the operator in mind. They have vibration-dampened platforms and cabins with controlled air quality, which reduces operator fatigue. When workers aren't as tired, they make fewer mistakes, and that cuts down on waste related to human error by 60%. Infrared barrier systems create a 360-degree protective zone around the cutting operations. If a person gets within 1.5 meters of the danger zone, the system immediately shuts down the equipment. These safety features not only meet the strict OSHA standards but also contribute to a 12 - 18% reduction in energy consumption. By optimizing the way the equipment operates, they ensure that energy isn't wasted during unnecessary starts and stops.