Understanding Production Requirements for Industrial Sawmill Operations

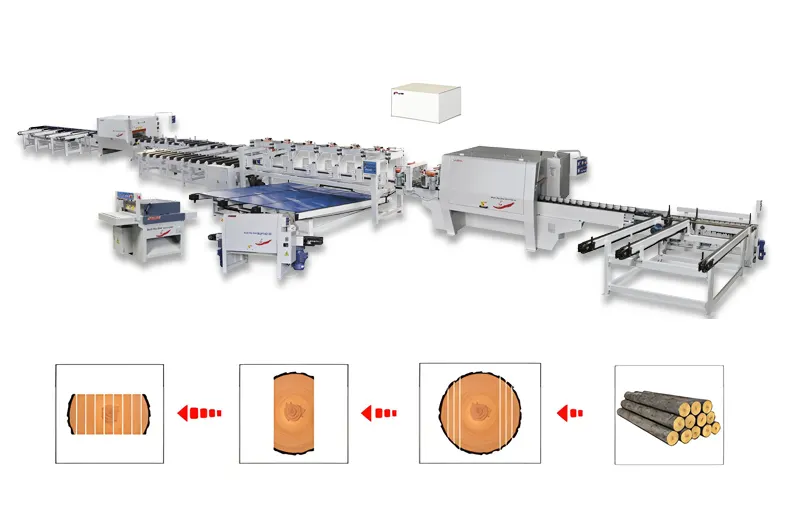

Choosing the perfect sawmill line is a bit like planning a big road trip. You need to know where you're going and what you'll encounter along the way. In the case of an industrial sawmill, that means taking a close look at your daily processing volumes and the characteristics of the raw materials you'll be working with. You have to consider things like the diameters of the logs, how much the wood species vary, and the dimensions of the finished products you want to produce. A sawmill line built to handle 100 tons of logs a day is very different from one designed for 500 tons. The differences show up in important aspects like how durable the blades need to be and how automated the sorting process should be. And let's not forget about the environment where the sawmill operates. If you're processing tropical hardwoods, for example, you'll need a cutting system that's reinforced and has advanced thermal compensation features. This helps keep the cutting precise even when the workload is heavy, just like you'd need a sturdy vehicle and proper cooling for a long, tough drive.

Optimizing Efficiency Through Advanced Sawmill Technology

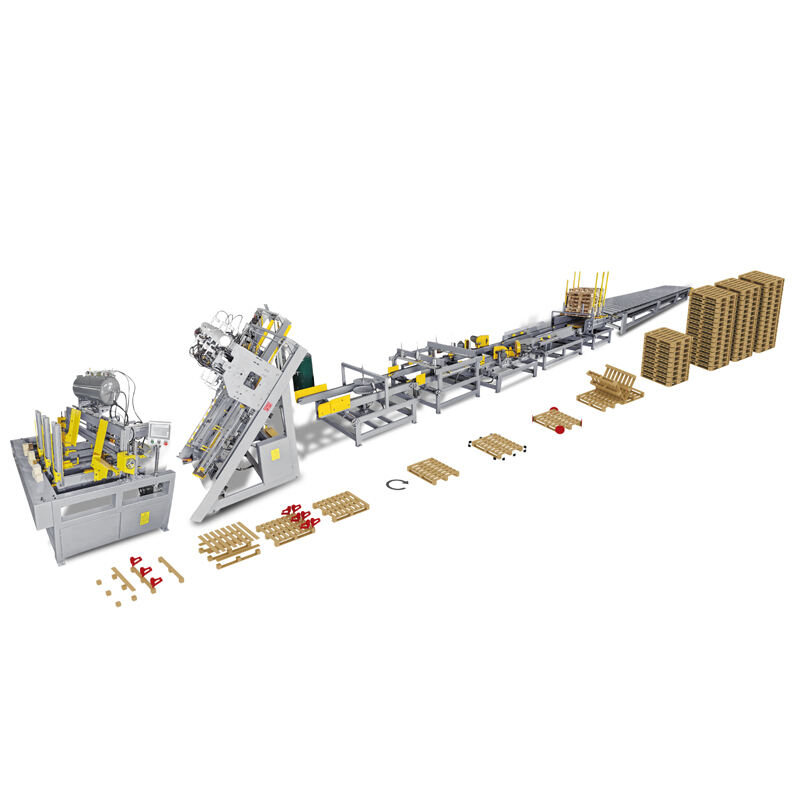

Today's sawmill lines are equipped with some pretty amazing technology that's like having a team of smart assistants working behind the scenes. Predictive maintenance systems are one of these game-changers. They analyze things like vibration patterns and thermal signatures of the machinery, which helps predict when something might go wrong and stop unplanned downtime in its tracks. Variable frequency drives on the feed mechanisms are another great feature. They can adjust the speed of the sawmill in real-time based on the density of the logs, kind of like a car adjusting its speed as it goes up or down a hill. This can reduce energy consumption by up to 18% compared to older, fixed-speed systems. Integrated moisture detection sensors are also important. They automatically adjust the drying parameters, ensuring that the lumber comes out with consistent quality and minimizing any damage from heat. And for operations that need to switch between different products quickly, modular engineered sawmill production line designs are a lifesaver. They allow you to change the cutting sequences and sorting parameters without having to spend a lot of time on manual recalibration, keeping the production process smooth and efficient.

Customized Solutions for Diverse Lumber Output Specifications

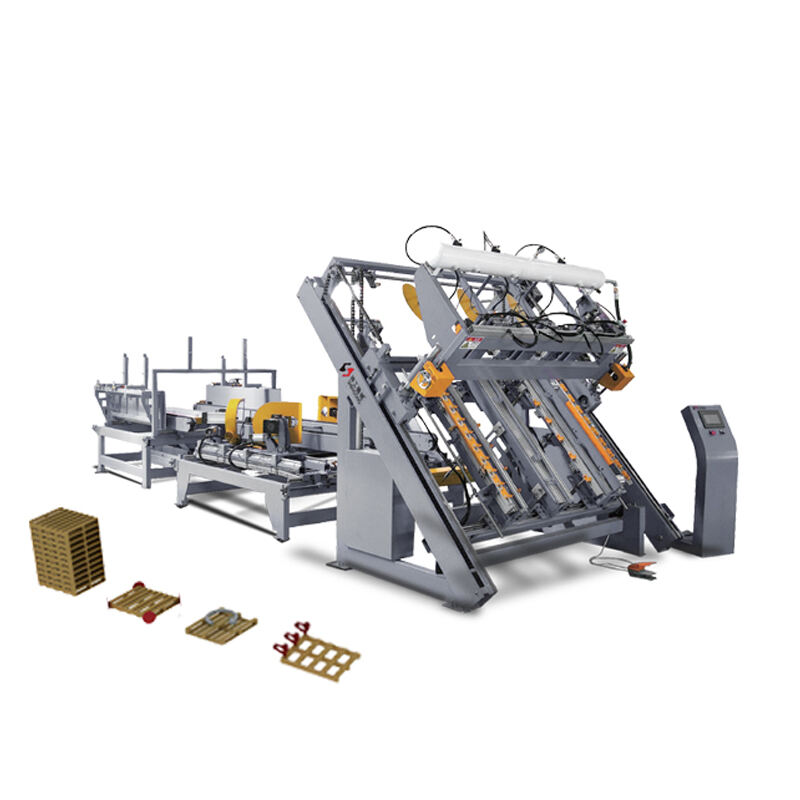

Just like every home has different needs, every sawmill operation has its own unique requirements when it comes to the lumber it produces. For facilities that make structural beams, they need heavy-duty horizontal resaw systems with laser-guided positioning that's accurate within 0.15mm. It's like having a super-precise measuring tape for the sawmill. If your focus is on getting veneer-quality cuts, twin circular saw configurations are the way to go. These saws can automatically switch between the primary and finishing blades, ensuring a smooth and high-quality finish. In places where you're processing a mix of different wood species, adaptive tension control systems are crucial. They keep the band saw stable, no matter how much the density of the wood changes. And in regions with high humidity, climate-controlled dust extraction systems are essential. They not only help maintain the precision of the cutting but also ensure that the workplace meets strict safety standards, creating a healthy and efficient working environment.

Reducing Lifetime Maintenance Costs in Sawmill Operations

Taking care of a sawmill is a bit like taking care of a car. You want to do regular maintenance to keep it running smoothly and avoid costly breakdowns. In the world of sawmills, proactive maintenance planning starts with choosing the right components. Carbide-tipped blades with nano-coating technologies are a great example. They can last 40% longer in tough, abrasive cutting conditions, just like high-quality tires can last longer on rough roads. Centralized lubrication systems with programmable interval controls are also important. They make sure the gears are properly protected and can reduce grease consumption by 25%. Predictive analytics platforms are another key tool. They analyze things like motor current draw patterns and bearing wear rates, allowing you to schedule parts replacement during planned downtime, so you don't have to deal with unexpected breakdowns. And water-cooled guide systems have proven to be very effective. They keep the blades at the right operating temperature during continuous production runs, extending their lifespan and saving you money in the long run.

Maximizing ROI Through Scalable Sawmill Configurations

Smart businesses always think about the future, and when it comes to sawmill operations, that means choosing a configuration that can grow with your needs. Forward-looking enterprises look for expansion-ready designs. These designs have standardized connection interfaces, which are like universal plugs that make it easy to add new equipment, and they also have overspecification in power distribution systems, ensuring there's enough power for future upgrades. Production lines with modular add-on capabilities are a big advantage. They let you increase your capacity gradually, without having to replace the entire system, which is great for operations that expect to grow by 30% each year. Energy recovery systems are another smart feature. They capture and reuse the thermal energy from the drying processes, which can offset up to 15% of the total power consumption of the facility. And with advanced simulation software, operators can now model different production scenarios. It's like running a test drive before actually making changes. This helps identify any bottlenecks in the production process before you physically implement them, allowing you to optimize equipment utilization during peak demand periods and get the most out of your investment.