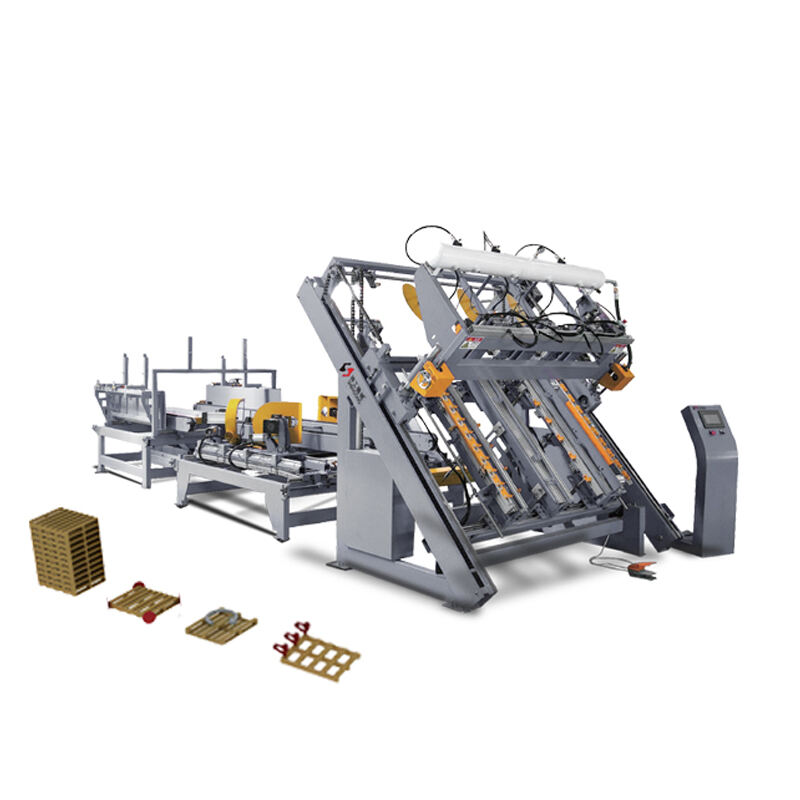

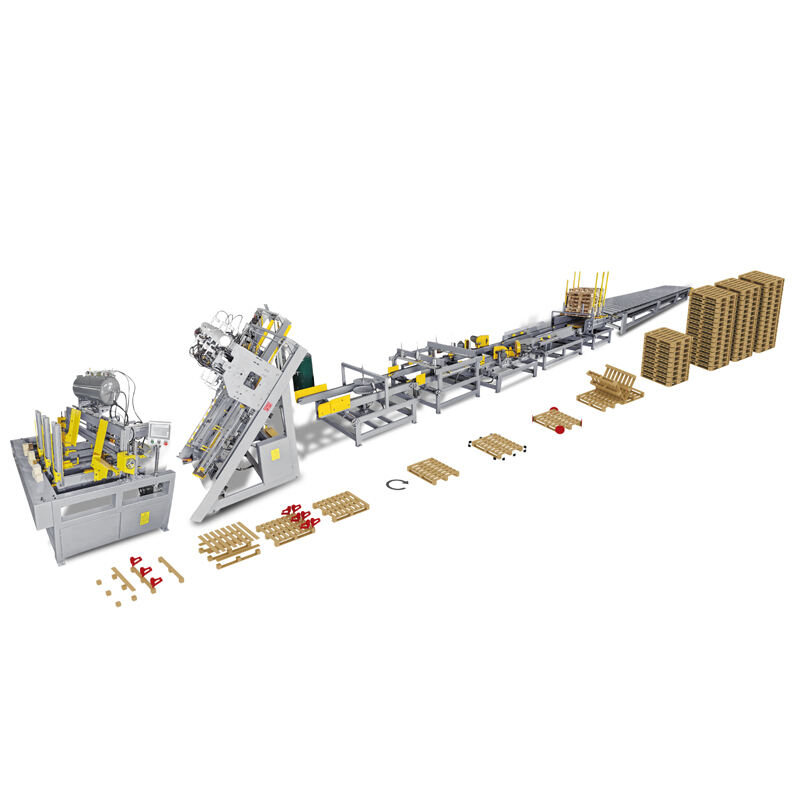

Key Indicators of a High - Performance Pallet Nailing Machine

In today's pallet manufacturing world, things are moving fast. You need a machine that can keep up. A high - performance pallet nailing machine is like a well - trained athlete. It has to be both fast and precise. Think about it, if you're nailing pallets together, the nails need to be in the right place every time, no matter what kind of wood you're using. Some woods are denser than others, and the machine should be able to handle that without missing a beat. That's why it's so important for operators to look for machines with real - time monitoring. This is like having a little helper that keeps an eye on things. If something starts to go wrong, like the nails aren't being placed correctly or there's a jam, it can spot it right away before it turns into a big problem. Also, energy - efficient motors are great. They keep the machine running smoothly, especially when you're doing high - volume production. And adaptive pressure controls are like the machine's smart brain. They make sure everything works well, and it helps to minimize the time the machine has to stop, which is really important when you're trying to get a lot of pallets made.

Balancing Durability and Precision in Equipment Selection

Now that we know what makes a high - performance pallet nailing machine, let's talk about choosing the right one. When you're in the industrial - grade pallet manufacturing business, your machinery has to be tough. It's like having a workhorse that can keep going and going. You want a machine with a reinforced steel frame. This is like the machine's strong backbone. It can withstand continuous use without breaking down. And then there are laser - guided positioning systems. These are super accurate, like a GPS for the nails. They can keep the precision at the millimeter level, even after years of use. Another thing to consider is advanced vibration dampening technology. When you're working with reclaimed or irregular timber, which is becoming more common in sustainable manufacturing, there can be a lot of vibrations. This technology helps to reduce those vibrations, which in turn helps to make the parts of the machine last longer.

Safety Protocols for Automated Pallet Production Lines

Once you have the right machine, safety is a top priority. In modern automated pallet production lines, just having a basic emergency stop button isn't enough. It's like having a bike with only one brake. You need more. Modern facilities use multi - sensor detection arrays. It's like having a group of watchful eyes. These sensors can tell if something that shouldn't be there, like a foreign object, enters the work area. If that happens, the machine stops right away. Ergonomic design elements are also really important. For example, adjustable control panels make it easier for workers to use the machine, especially during long shifts. And noise - reduction housings are like a pair of earplugs for the workers. They help to make the work environment more comfortable. Automated lubrication systems are also a great addition. They make sure the parts of the machine don't overheat, which can be a fire risk.

Optimizing Maintenance Cycles for Peak Performance

To keep your pallet nailing machine performing at its best, maintenance is key. In the past, we used to do maintenance at fixed intervals, like changing the oil in your car every 3,000 miles. But now, there are better ways. Predictive maintenance algorithms are like fortune - tellers for your machine. They can look at how the machine is actually wearing out and tell you when it needs servicing. They do this by using IoT - enabled sensors. These sensors can track things like the temperature of the bearings, the pressure in the hydraulics, and the load on the motor. By knowing these things, you can predict when something might go wrong and fix it before it causes a breakdown. This is really important, especially when you're making export - grade pallets. The nails have to go in at the right depth every time, and proper maintenance helps to make sure that happens.

Cost - Effective Upgrades for Existing Pallet Systems

What if you already have an older pallet nailing machine? Don't worry, there are ways to make it better without having to buy a whole new one. You can retrofit it with modular automation kits. It's like giving your old car a new engine. These kits can boost the productivity of your machine by 30 - 45%. Upgradable software packages are also really useful. They can connect your machine to an enterprise resource planning (ERP) system. This is like having a big brain that helps you keep track of materials and make sure the quality is good. Energy recovery systems are another great upgrade. They can save power by repressurizing the hydraulic accumulators when the machine is not in use. So, you can make your existing machine better and more efficient without spending a fortune.

Future - Proofing Your Operation Through Smart Technology

Looking to the future, smart technology is going to change the game in pallet manufacturing. Machine learning algorithms are like a super - smart assistant for your pallet nailing machine. They can analyze the wood grain and automatically adjust the nailing patterns. It's like the machine is thinking for itself. Cloud - connected diagnostics are also really cool. They can show you how your machine is performing compared to similar machines all over the world. And augmented reality interfaces are like having a virtual technician with you. They can show you step - by - step how to fix complex mechanical problems. By using these smart technologies, you can make sure your pallet manufacturing operation is ready for whatever the future brings.